Hi everyone-

My name is Rick, and I run Absolute-Wood. We've made vape stands since late 2011. I've been a Mechanical Designer for over 20 years and have designed a great array of products over the years. Please visit our forum here to learn more about us.

With Deeming, I finally decided to give in and design some mods-

Well, been busy designing at my 3D Workstation-

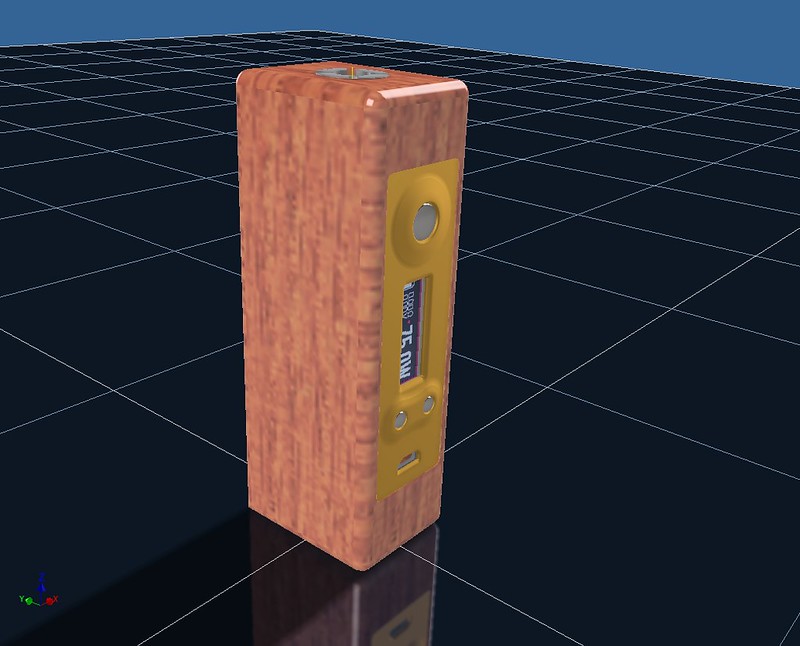

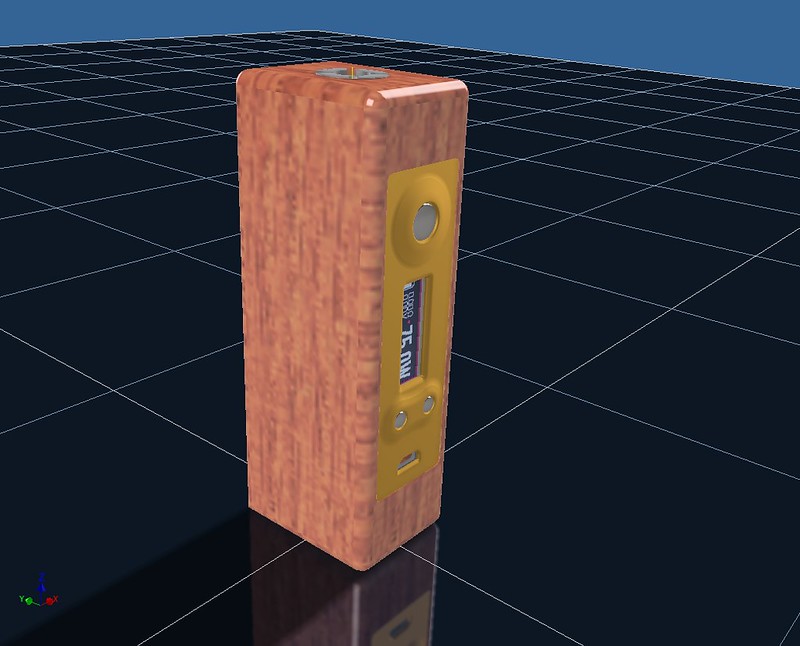

Stainless Steel Faceplate & Buttons shown.

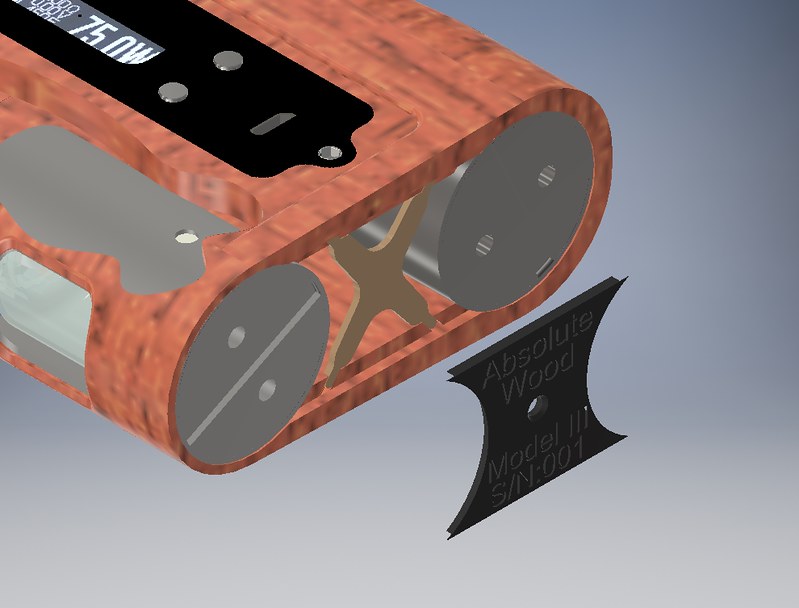

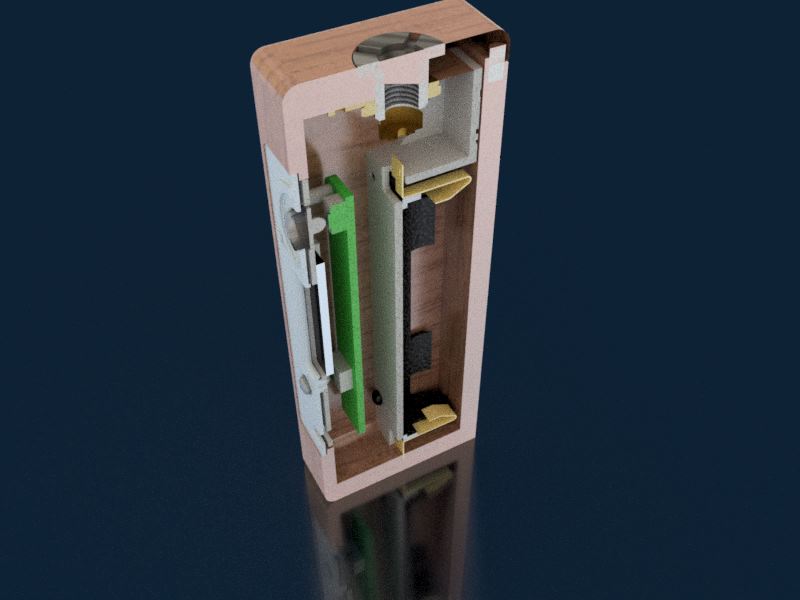

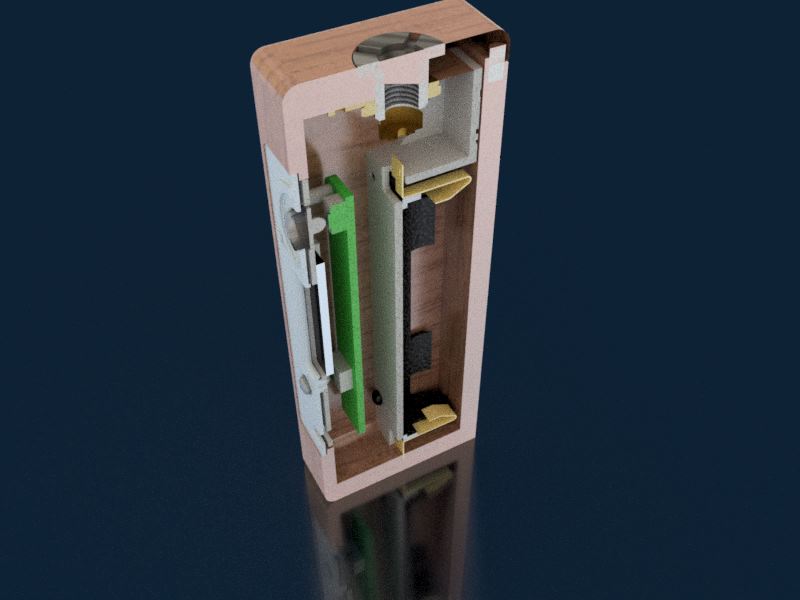

View of the PV "chopped" in half, exposing the inner structures.

Modeled in a single block of Oak for the moment. All USA parts, US designed and manufactured.

The parts used include the Evolv DNA75 chipset with temp control & much more, a Fat Daddy's 510 Woody connector and a Keystone battery sled.

Part of the design includes a handful of 3D Printed parts including the chipset mount/button pusher; the battery sled holder & the Faceplate.

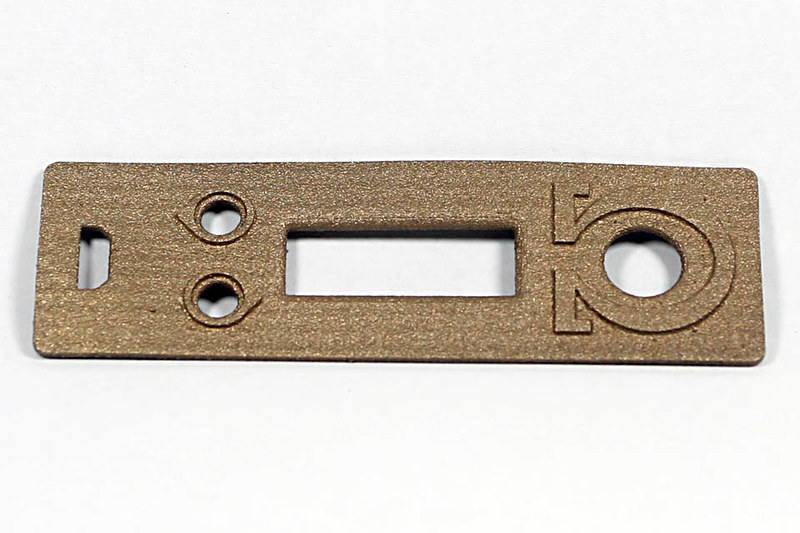

So far, I've created three different Faceplates. A flat, featureless basic Face; a flat version "Ohm" Faceplate (shown above), and a Faceplate with a contoured surface that provides a buildup around the buttons to prevent accidental firing:

The Faceplates (and buttons) will be available in Plastic, Stainless Steel & Brass (shown above).

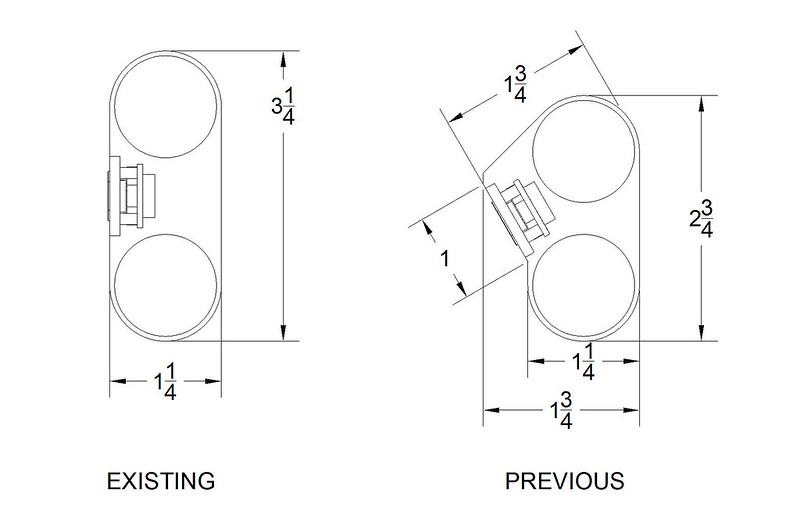

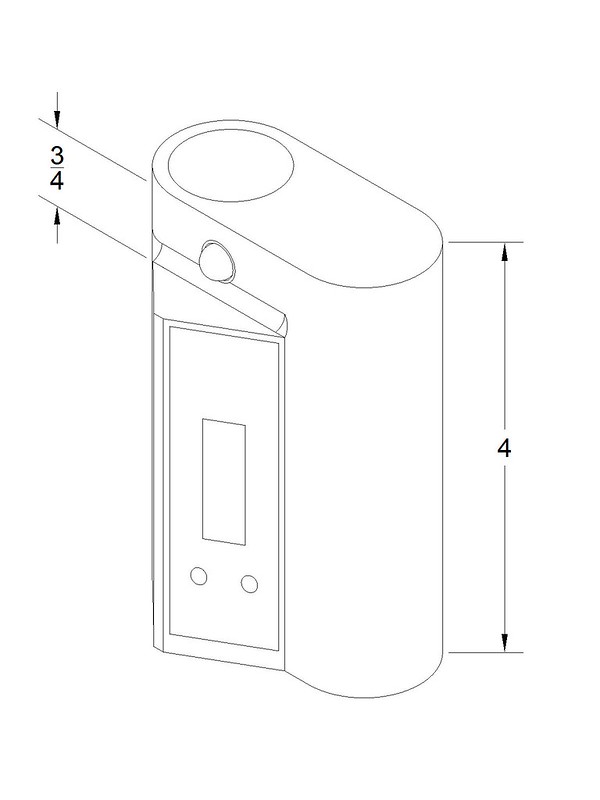

This MOD is the first design - a single 18650 DNA75 made as reasonably small as possible:

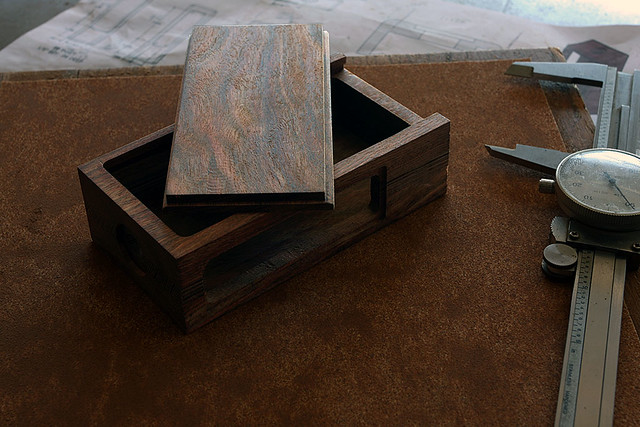

1-1/4"w x 1-5/8"d x 4-3/8"h. The battery access door is on the edge opposite the Faceplate, slides open and closed, and uses magnets to hold the closed position.

I made a simple animation of the complete PV coming apart & it shows the door sliding out. I was able to copy it from Facebook-

An raytraced frame from the animation:

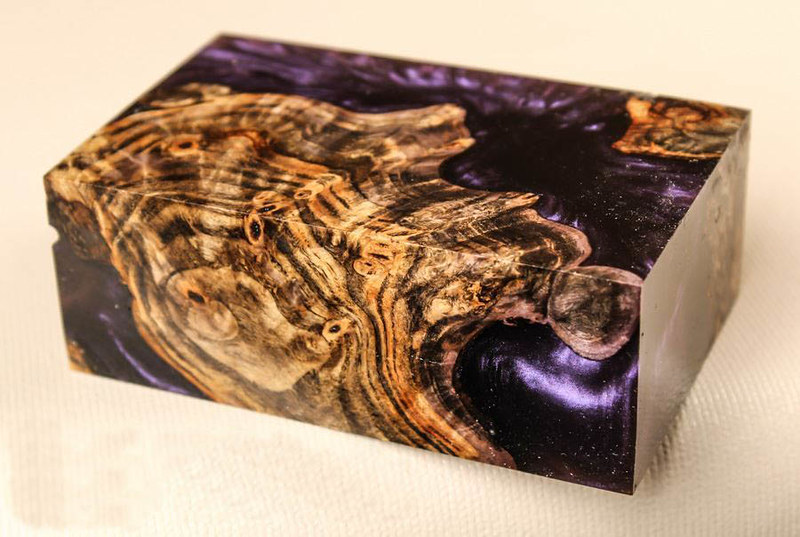

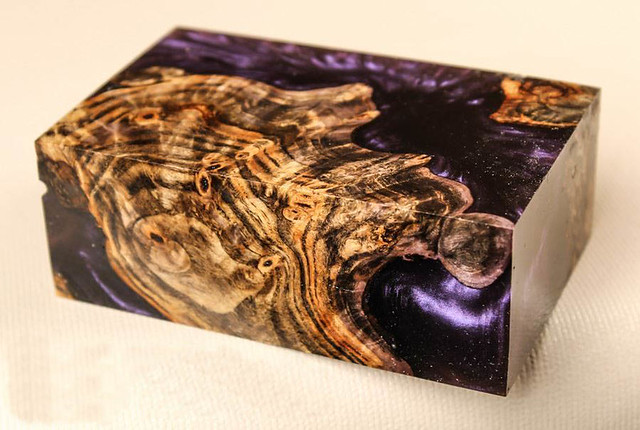

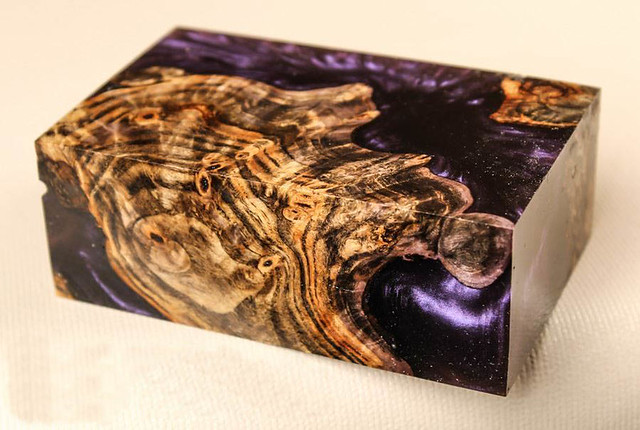

The doors are cut from the block early in the production process, so they will match the grain when in place. Three different versions of the bodies will be produced - single species solid block; multi-layered, multi species laminated blocks (like our vape stands); and stabilized wood/resin blocks similar to:

This is from one of my favorite sellers on FleaBay.

As said, this single 18650 version is the first design. A very similar dual 18650 version with the sliding door on the side is currently on the drawing board. A third, Side by Side style is also in my head and waiting to be designed after the dual battery MOD is designed next.

Also considering looking into 26650 possibilities too. Well, whatever I can finalize designs on and have available for order by August 8th...

I still have to order some 3D printed parts to test out sizing and looks before we can build the initial test units. Need to test machining methods and work out proper order of operations, etc...

They will actually be two DNA40's from dis-assembled new PV's (bought for this) and one with a new DNA75 chipset. Probably one in single species with a plastic faceplate, multi lamination version, and I have a pretty cool purple, blue, slate and orange piece of stabilized maple burl I will probably utilize for one of them.

Sorry, but the three test units already have been assigned for local evaluation.

Pricing has not been determined yet, but should start out under $200, possibly less - for a DNA75 MOD that is 100% US made, parts and labor

I've even been playing around modeling some custom fire buttons, too...

More updates as they happen-

Rick

My name is Rick, and I run Absolute-Wood. We've made vape stands since late 2011. I've been a Mechanical Designer for over 20 years and have designed a great array of products over the years. Please visit our forum here to learn more about us.

With Deeming, I finally decided to give in and design some mods-

Well, been busy designing at my 3D Workstation-

Stainless Steel Faceplate & Buttons shown.

View of the PV "chopped" in half, exposing the inner structures.

Modeled in a single block of Oak for the moment. All USA parts, US designed and manufactured.

The parts used include the Evolv DNA75 chipset with temp control & much more, a Fat Daddy's 510 Woody connector and a Keystone battery sled.

Part of the design includes a handful of 3D Printed parts including the chipset mount/button pusher; the battery sled holder & the Faceplate.

So far, I've created three different Faceplates. A flat, featureless basic Face; a flat version "Ohm" Faceplate (shown above), and a Faceplate with a contoured surface that provides a buildup around the buttons to prevent accidental firing:

The Faceplates (and buttons) will be available in Plastic, Stainless Steel & Brass (shown above).

This MOD is the first design - a single 18650 DNA75 made as reasonably small as possible:

1-1/4"w x 1-5/8"d x 4-3/8"h. The battery access door is on the edge opposite the Faceplate, slides open and closed, and uses magnets to hold the closed position.

I made a simple animation of the complete PV coming apart & it shows the door sliding out. I was able to copy it from Facebook-

An raytraced frame from the animation:

The doors are cut from the block early in the production process, so they will match the grain when in place. Three different versions of the bodies will be produced - single species solid block; multi-layered, multi species laminated blocks (like our vape stands); and stabilized wood/resin blocks similar to:

This is from one of my favorite sellers on FleaBay.

As said, this single 18650 version is the first design. A very similar dual 18650 version with the sliding door on the side is currently on the drawing board. A third, Side by Side style is also in my head and waiting to be designed after the dual battery MOD is designed next.

Also considering looking into 26650 possibilities too. Well, whatever I can finalize designs on and have available for order by August 8th...

I still have to order some 3D printed parts to test out sizing and looks before we can build the initial test units. Need to test machining methods and work out proper order of operations, etc...

They will actually be two DNA40's from dis-assembled new PV's (bought for this) and one with a new DNA75 chipset. Probably one in single species with a plastic faceplate, multi lamination version, and I have a pretty cool purple, blue, slate and orange piece of stabilized maple burl I will probably utilize for one of them.

Sorry, but the three test units already have been assigned for local evaluation.

Pricing has not been determined yet, but should start out under $200, possibly less - for a DNA75 MOD that is 100% US made, parts and labor

I've even been playing around modeling some custom fire buttons, too...

More updates as they happen-

Rick

Last edited:

. Sorry for this, but we're still having some issues with vendors, and I'm looking into a new vendor to Cerakote the Faceplates and other exposed metals.

. Sorry for this, but we're still having some issues with vendors, and I'm looking into a new vendor to Cerakote the Faceplates and other exposed metals.