I really like this topic because I see a lot of pro coil builders here

Unfortunately I am just an amateur / hobbist / newbie coil builder.

Maybe some of my heaters to say Hello! (3 random triptychs)...

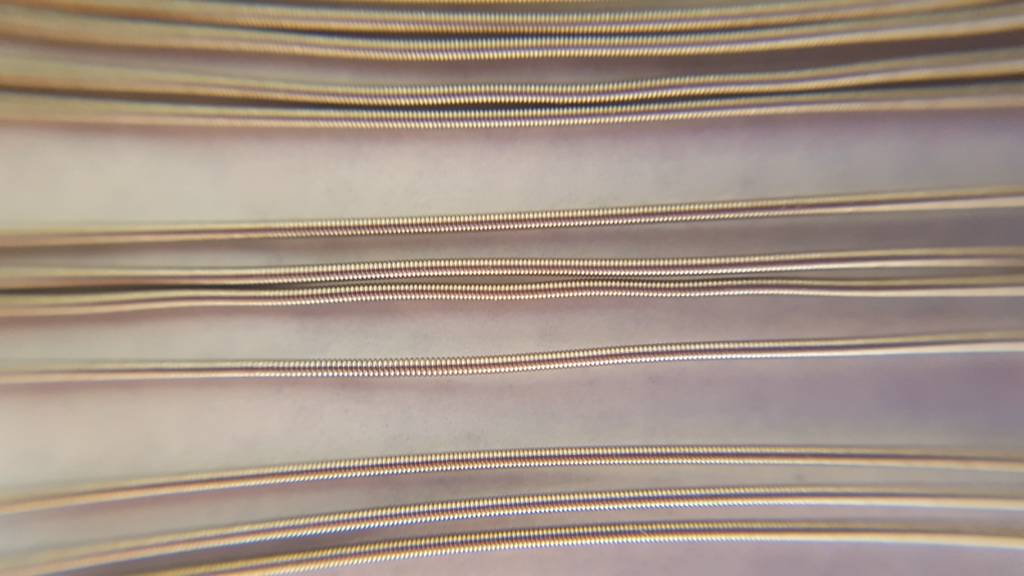

1. 7-Loops Reversible Celtic Braid additionally flattened and polished (mirror on the inner and outer layer)... Final resistance: 0,247Ohm(dual)... Flat like a sheet of paper: 7 x 2 x 0,16mm Kanthal D...

2. Final resistance: 0,478Ohm... Stitched Mohawk: 2 x 0,25mm + 2 x 0,09mm... 4 sided Mohawk (X-Wing Alien): 2 x 0,25mm + (2+1) x 0,09mm... Kanthal D...

3. Miniature variation of SFC... Final resistance: 0,412Ohm (single)... Core 1 Micro Stitched Alien: 0,2mm + 2 x 0,08mm... Core 2 5-Loops Micro Braids x2: 5 x 2 x 0,1mm... Mid core: 2 x 0,3mm... Sides: 0,25mm... Wrapps: 0,08mm... Kanthal D...

Sorry for metric scale, but I have designed heaters in this scale, heatflux etc counts based on mm units and I think also in SI(International System of Units, AWG makes it difficult for me).

ill get some more wire ordered and try out a fused with 36g

ill get some more wire ordered and try out a fused with 36g