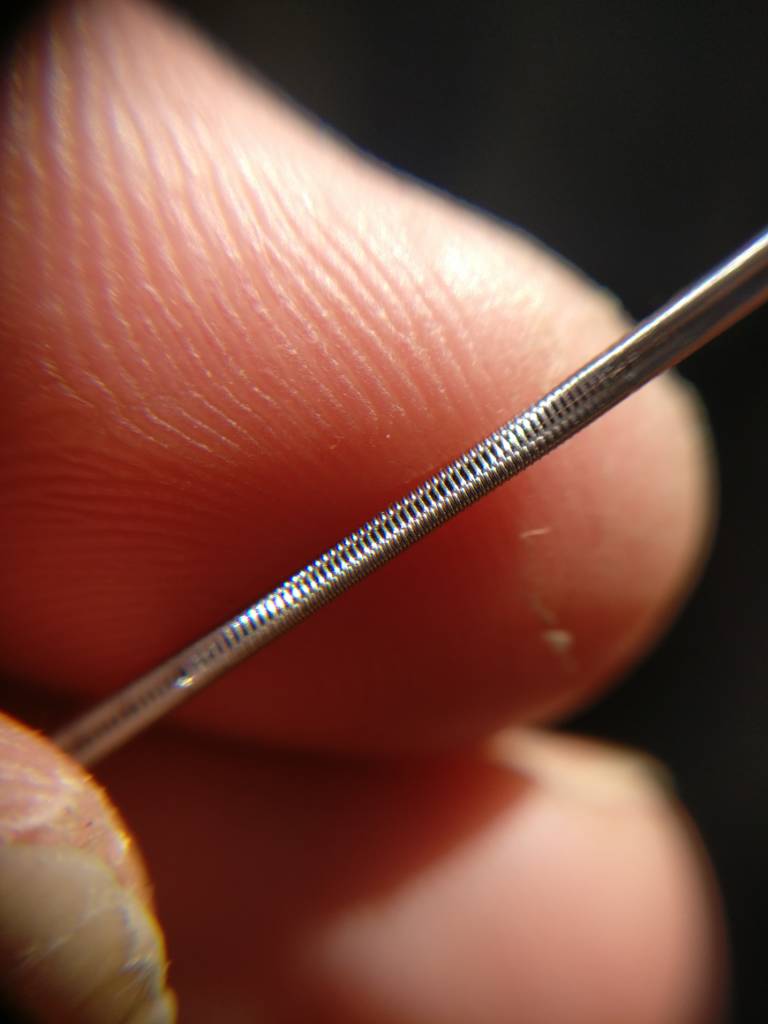

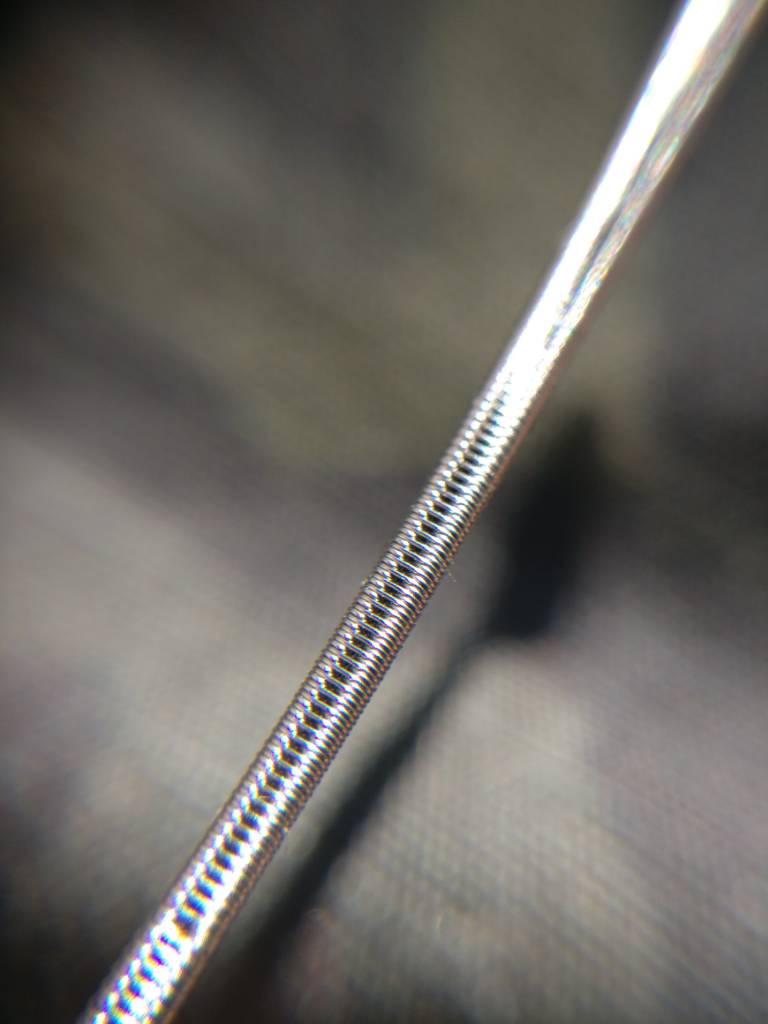

So I was doing more aliens today and got a little bored. I decided to try making some SFC wire for the hell of it.

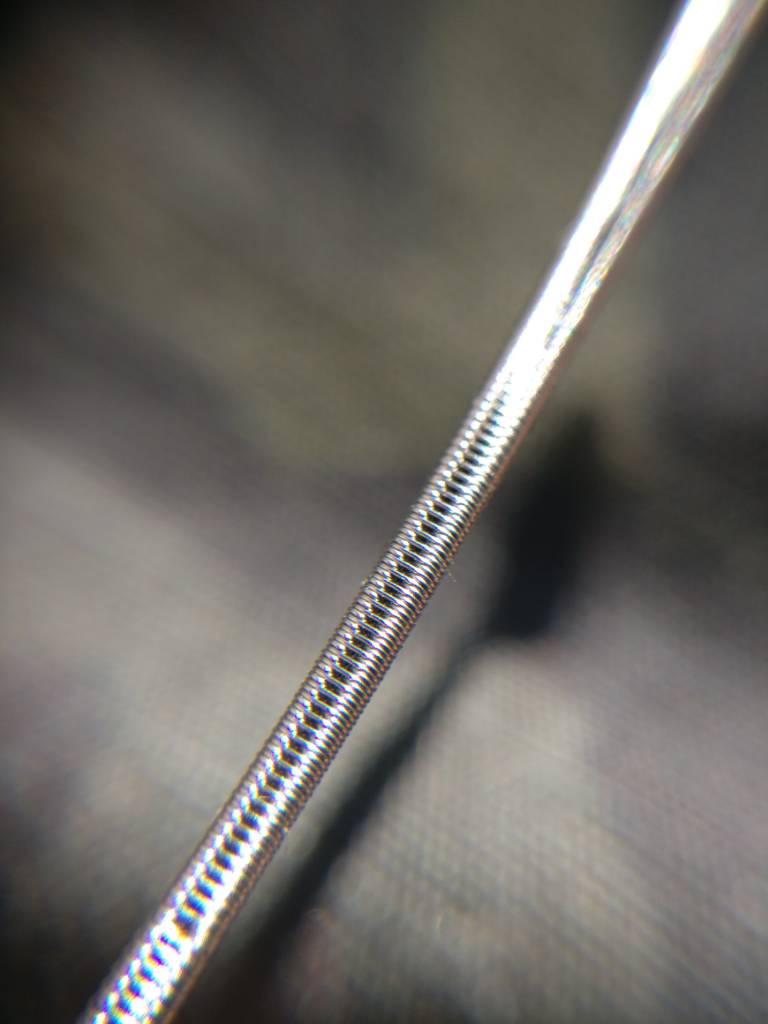

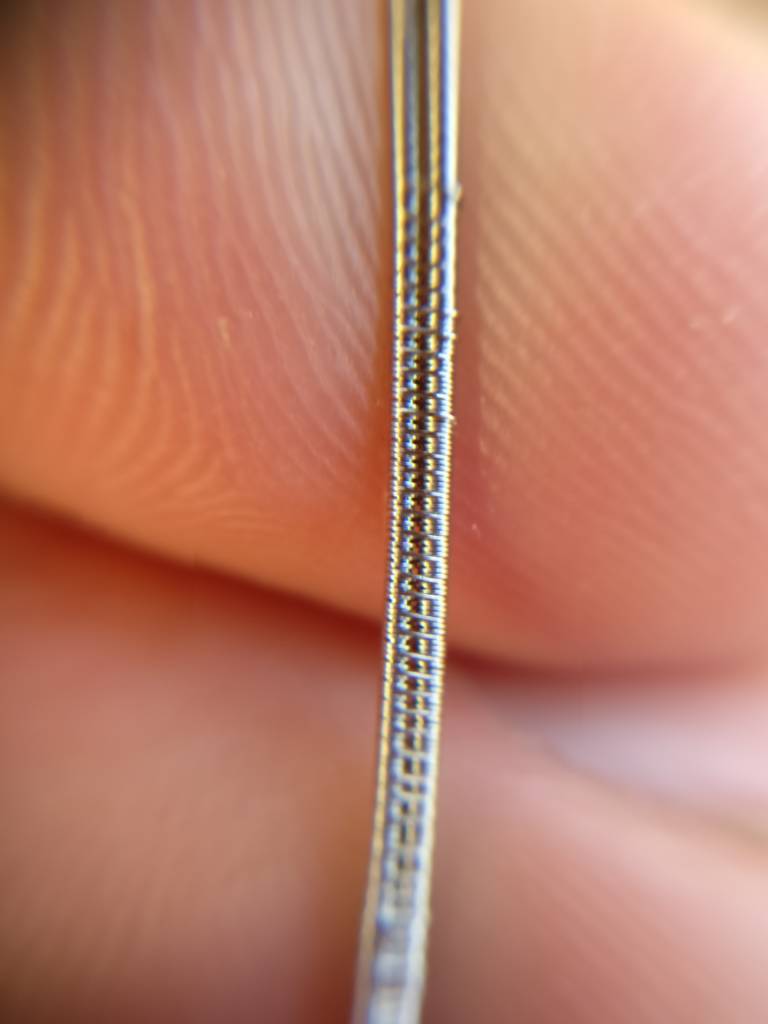

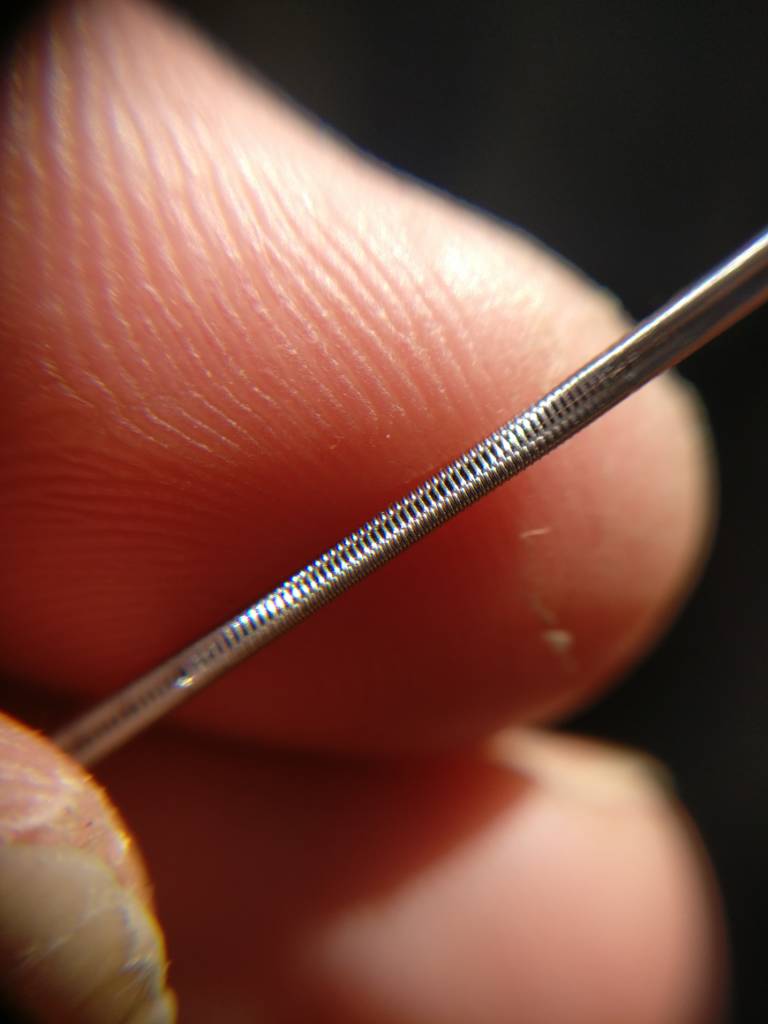

Went fairly well I guess. I had some skips and areas that were a consistent jump of two coils on the wrap. I would have preferred a jump of two the entire way, or no jumps at all.

What would *really* help is if I could set my camera up with the macro so that I could see what's going on better. As it stands I'm basically looking at light reflecting off the surface. Difficult but not impossible. I have enough wire for two good coils so I'm gonna throw them in the Kylin or goon.

Any tips are welcome!

2x24g Kanthal cores, spaced 36g SS 316l wraps, Fuse wrap is also 36g SS 316l.

My apologies for not having a better field of view with the macro!

Sent from my ONEPLUS A3000 using Tapatalk

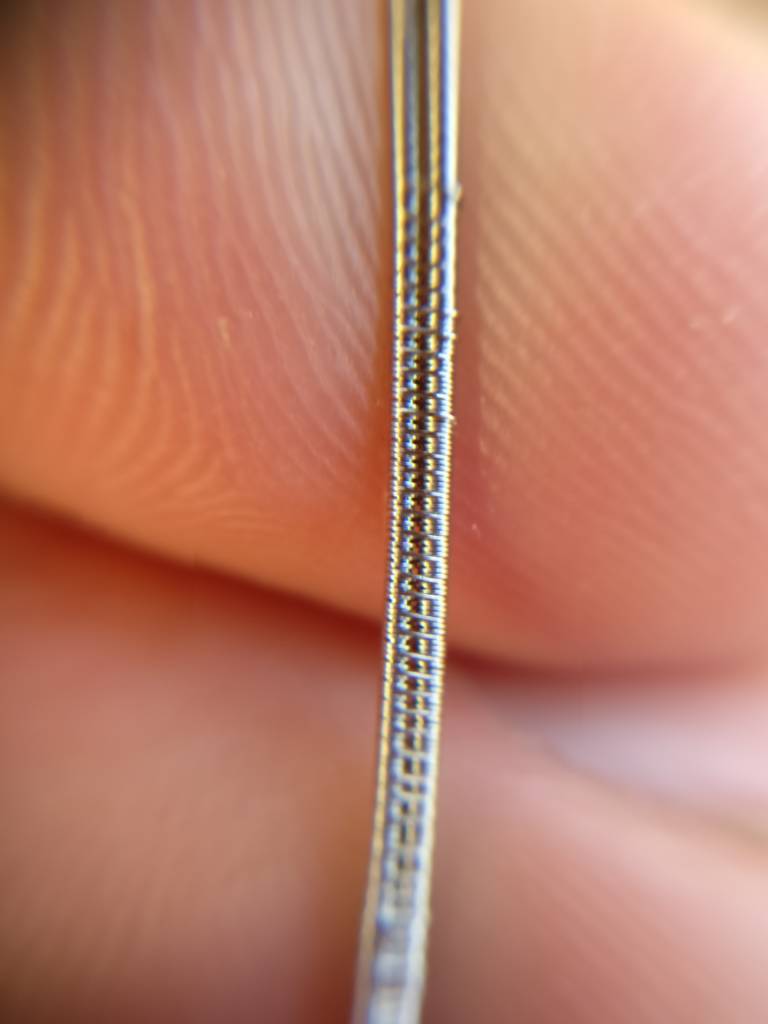

Went fairly well I guess. I had some skips and areas that were a consistent jump of two coils on the wrap. I would have preferred a jump of two the entire way, or no jumps at all.

What would *really* help is if I could set my camera up with the macro so that I could see what's going on better. As it stands I'm basically looking at light reflecting off the surface. Difficult but not impossible. I have enough wire for two good coils so I'm gonna throw them in the Kylin or goon.

Any tips are welcome!

2x24g Kanthal cores, spaced 36g SS 316l wraps, Fuse wrap is also 36g SS 316l.

My apologies for not having a better field of view with the macro!

Sent from my ONEPLUS A3000 using Tapatalk