Dhim

Silver Contributor

Member For 4 Years

Member For 3 Years

Member For 2 Years

Member For 1 Year

Reviewer

Member For 5 Years

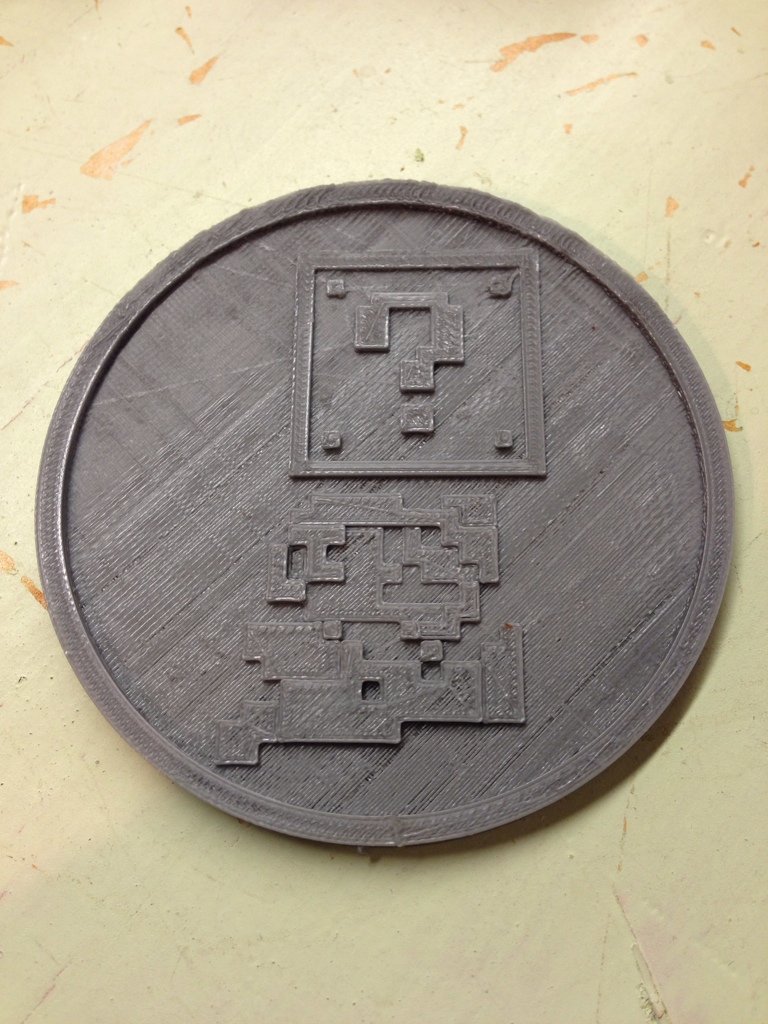

I absolutely love 3D printing and it seems like a lot of people still don't know much about it, so I figured I'd start a thread with some of the things I've printed with a 3D printer. A lot of things are vaping related, a lot are not. I'll probably keep this updated as a sort of live blog. If you 3D print, toss your stuff in here too!

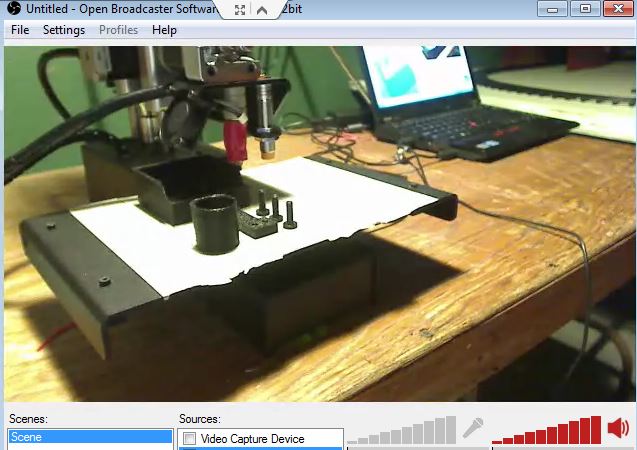

Printers used:

Makerbot Replicator v5

Printrbot Metal

To start off, my absolute favorite thing I've printed (yes I'm a nerd). A life sized to scale version of a lightsaber.

Single mod holder.

Starting to organize ze e-liquids.

Printers used:

Makerbot Replicator v5

Printrbot Metal

To start off, my absolute favorite thing I've printed (yes I'm a nerd). A life sized to scale version of a lightsaber.

Single mod holder.

Starting to organize ze e-liquids.