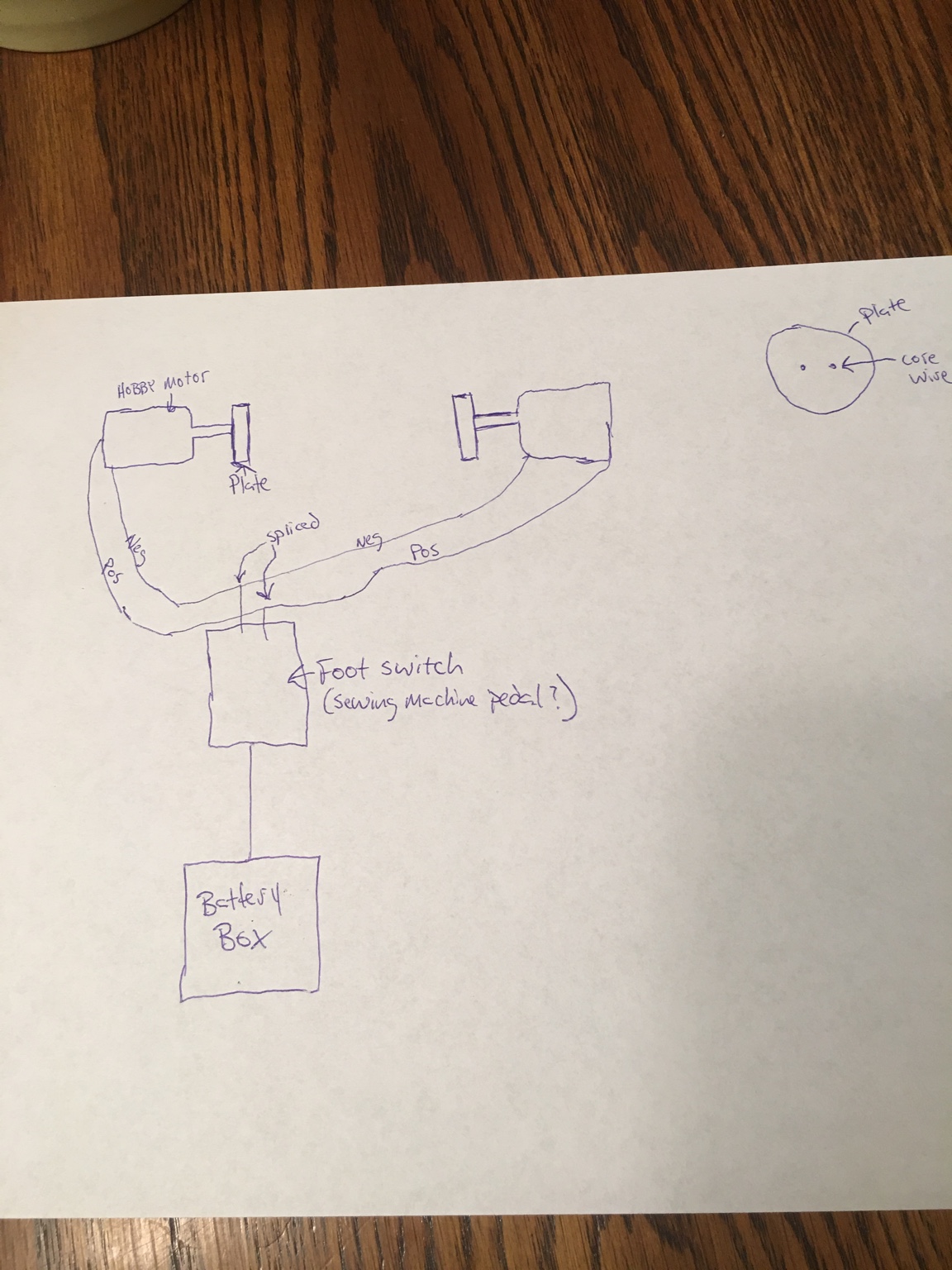

Bouncing an idea around in my head and hopefully someone with more electronics/robotics background can give their $.02.

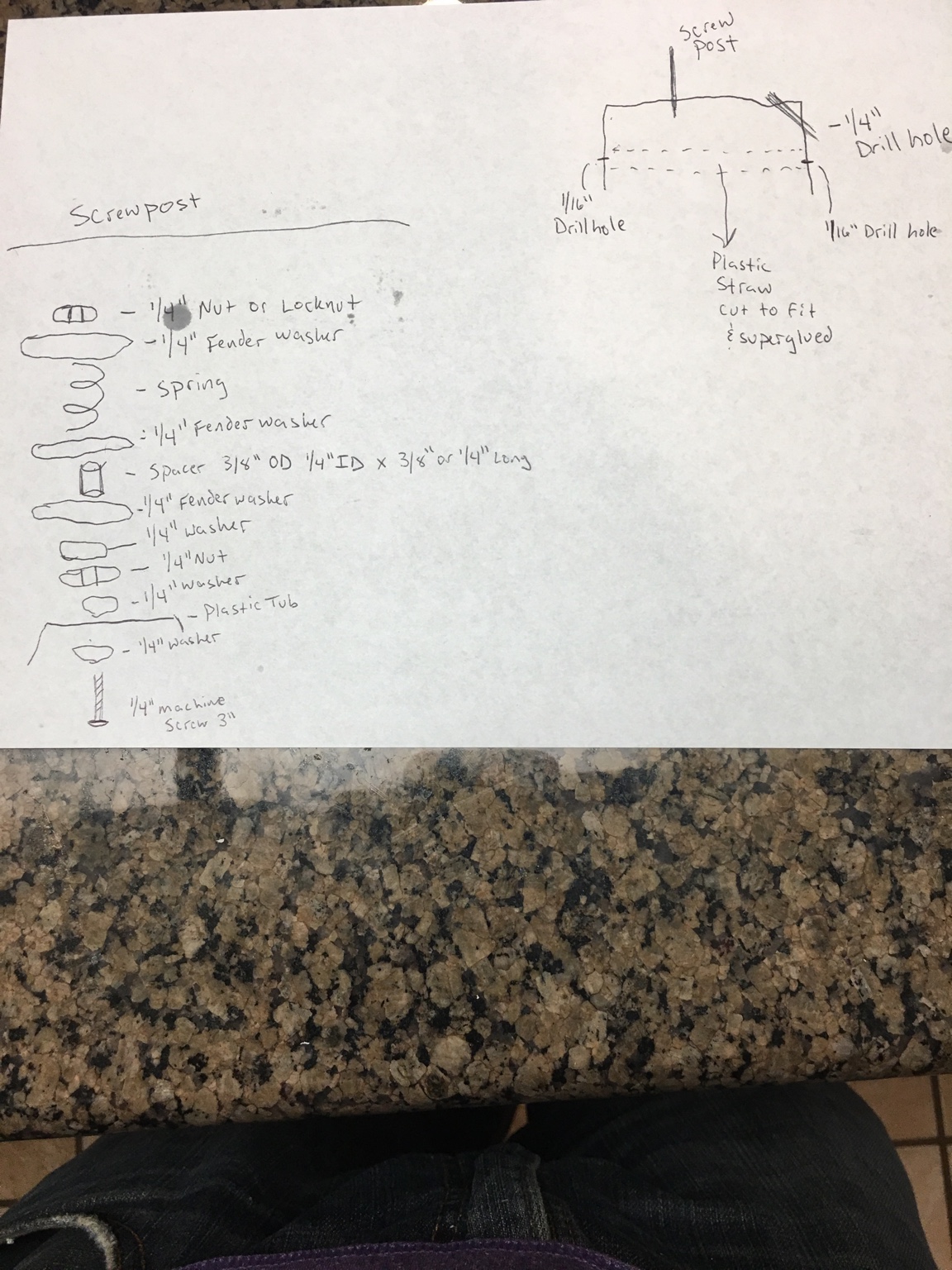

The basics of what I wanna try are 2 hobby motors attached to the same power source face to face (with opposite polarity)with a switch of some kind (ideally with a variable speed instantaneous control ie a cordless drill trigger). With a plate on each motor, facing eachother, with 2 holes for fused clapton cores.

In essence making a lathe with 2 driven sides.

Basically wanna eliminate the passive side (swivels) from the equasion. Still would, in theory, use a hand to control the wrap wire. But not end up with the few twists that always happen (or the many twists that happen on a bad day.)

Idk if this is a pipedream. If the cheap motors, attached to the same power source, are consistent enough in rpm's to not twist the core wires?

Any feedback from those smarter than me?

The basics of what I wanna try are 2 hobby motors attached to the same power source face to face (with opposite polarity)with a switch of some kind (ideally with a variable speed instantaneous control ie a cordless drill trigger). With a plate on each motor, facing eachother, with 2 holes for fused clapton cores.

In essence making a lathe with 2 driven sides.

Basically wanna eliminate the passive side (swivels) from the equasion. Still would, in theory, use a hand to control the wrap wire. But not end up with the few twists that always happen (or the many twists that happen on a bad day.)

Idk if this is a pipedream. If the cheap motors, attached to the same power source, are consistent enough in rpm's to not twist the core wires?

Any feedback from those smarter than me?