So, the spring on my RR2 is giving out to the point of having to adjust the battery rattle screw completely out of its threads and I was wondering where I might pick up a comparable replacement spring or upgrade to magnets.

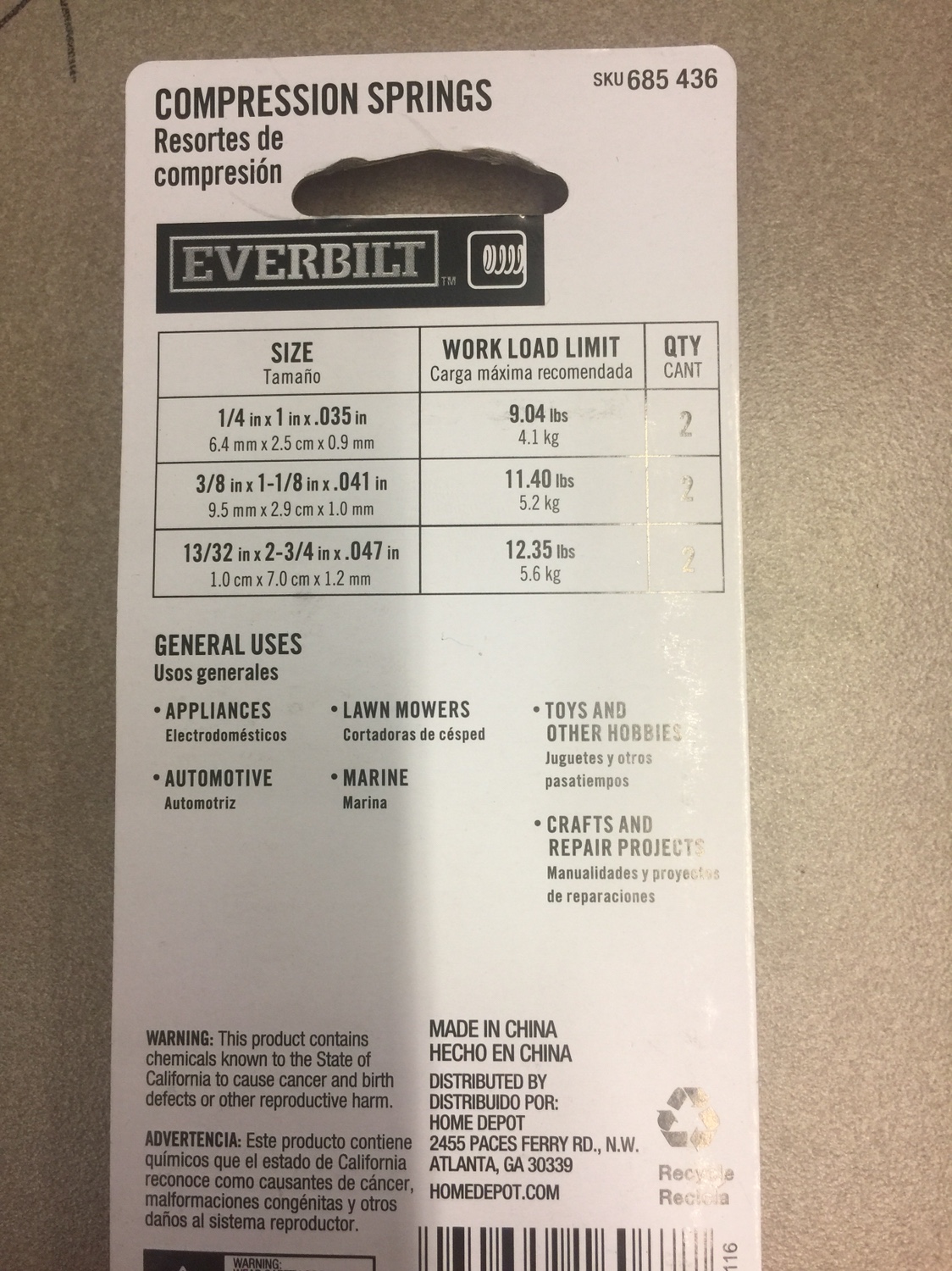

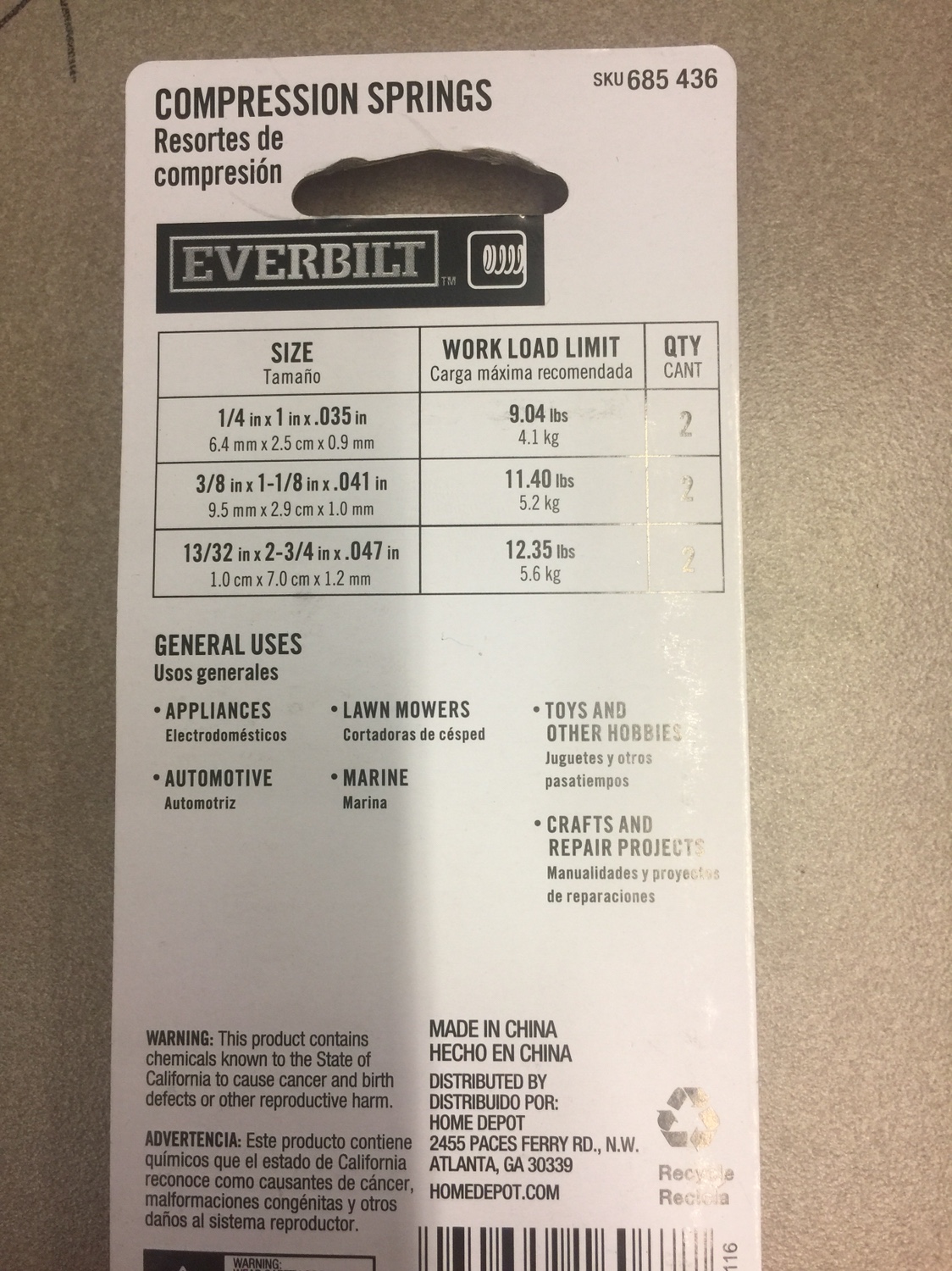

I’m not needing an exact replica of what I have and it doesn’t even have to be from a vape place...I work at a hardware store, but the only springs that would come close to working are these

But these contain Zinc and I’m not sure if the spring would generate enough heat to cause toxic elements to come out of it.

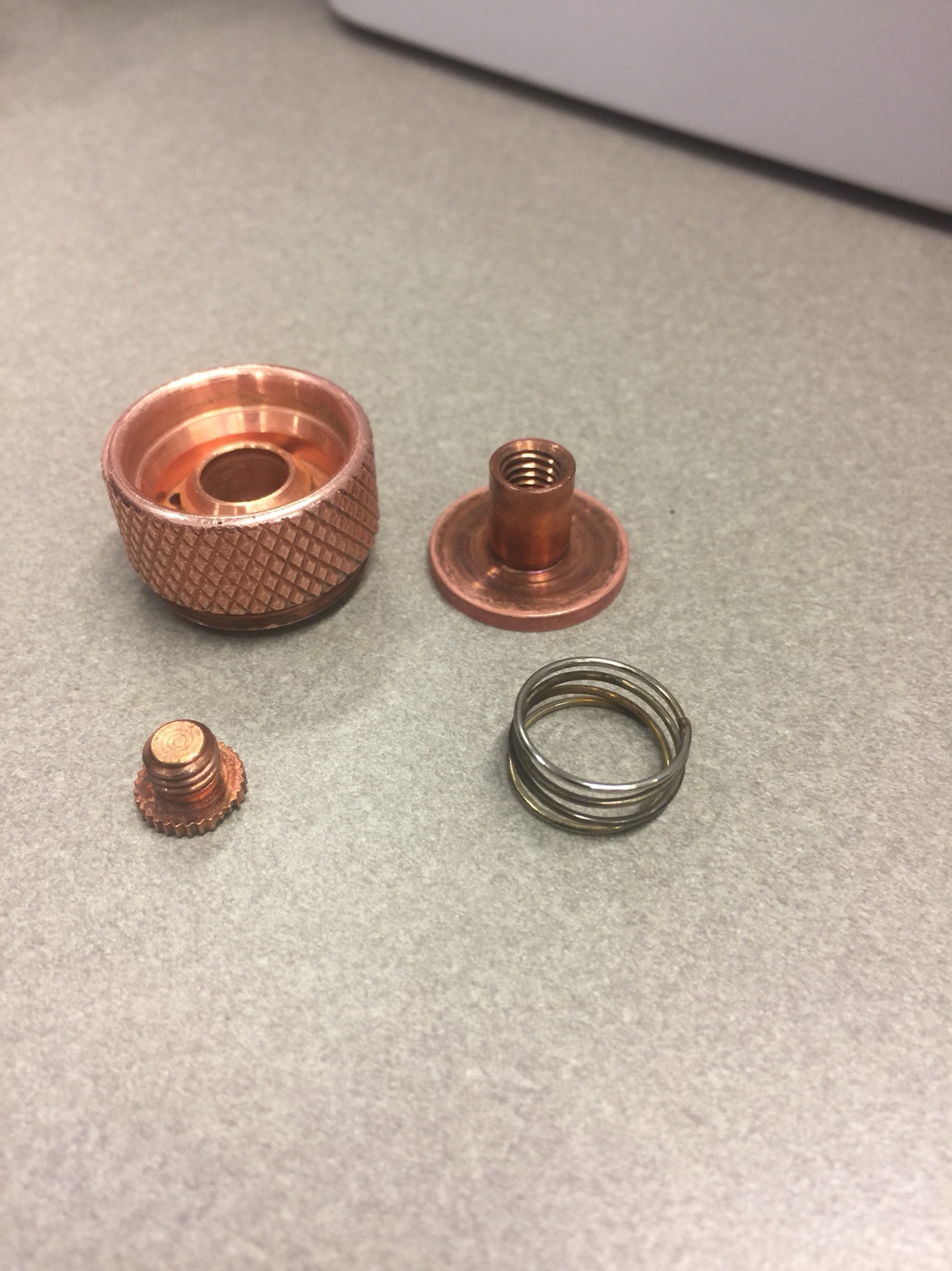

Here are some pics and measurements...if anyone knows of a nationwide store or a general idea of what type of store to look in, it would be greatly appreciated

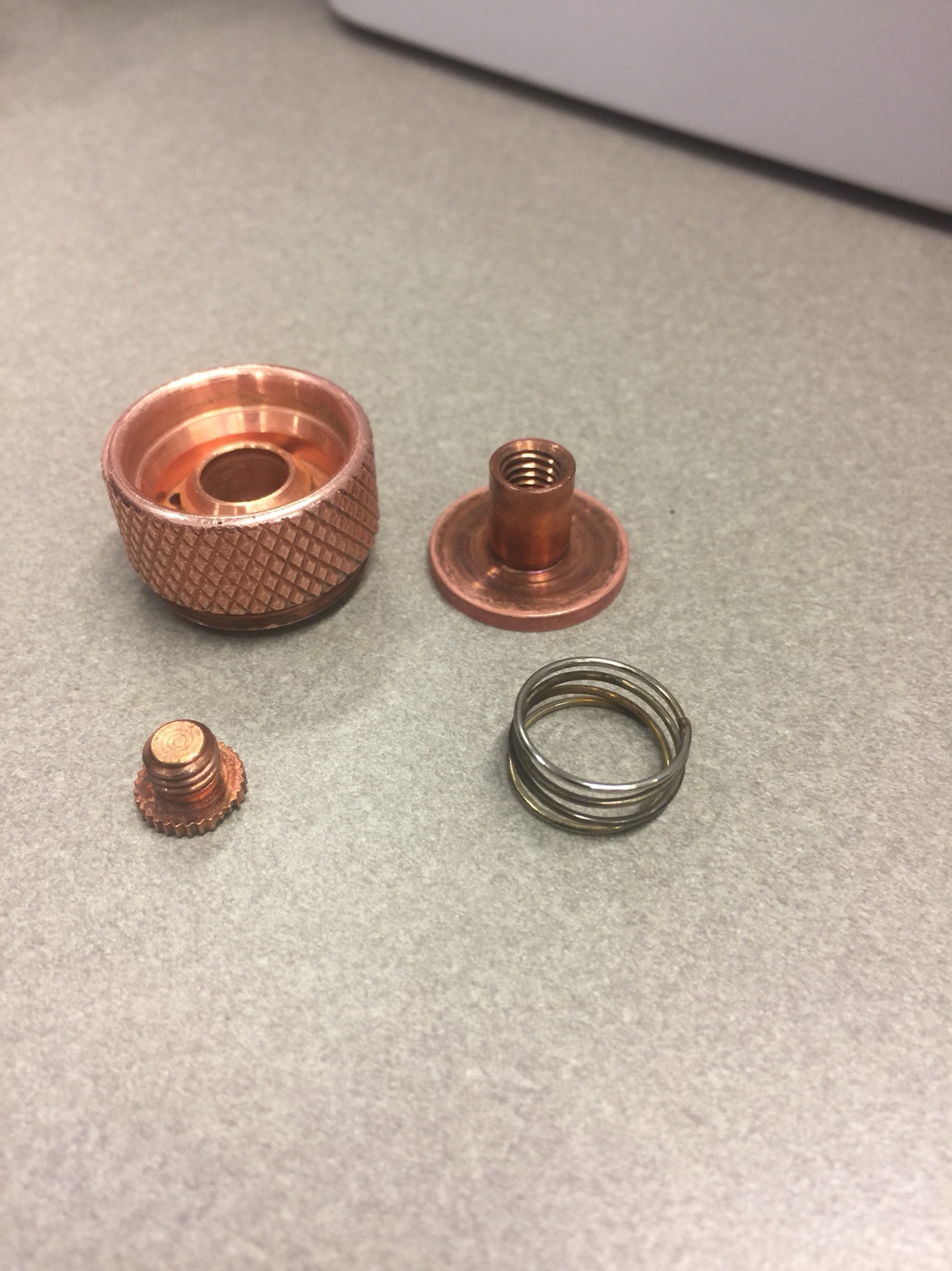

Looks like a half inch across

That’s the disc portion of the button with the post the spring/magnet needs to fit around

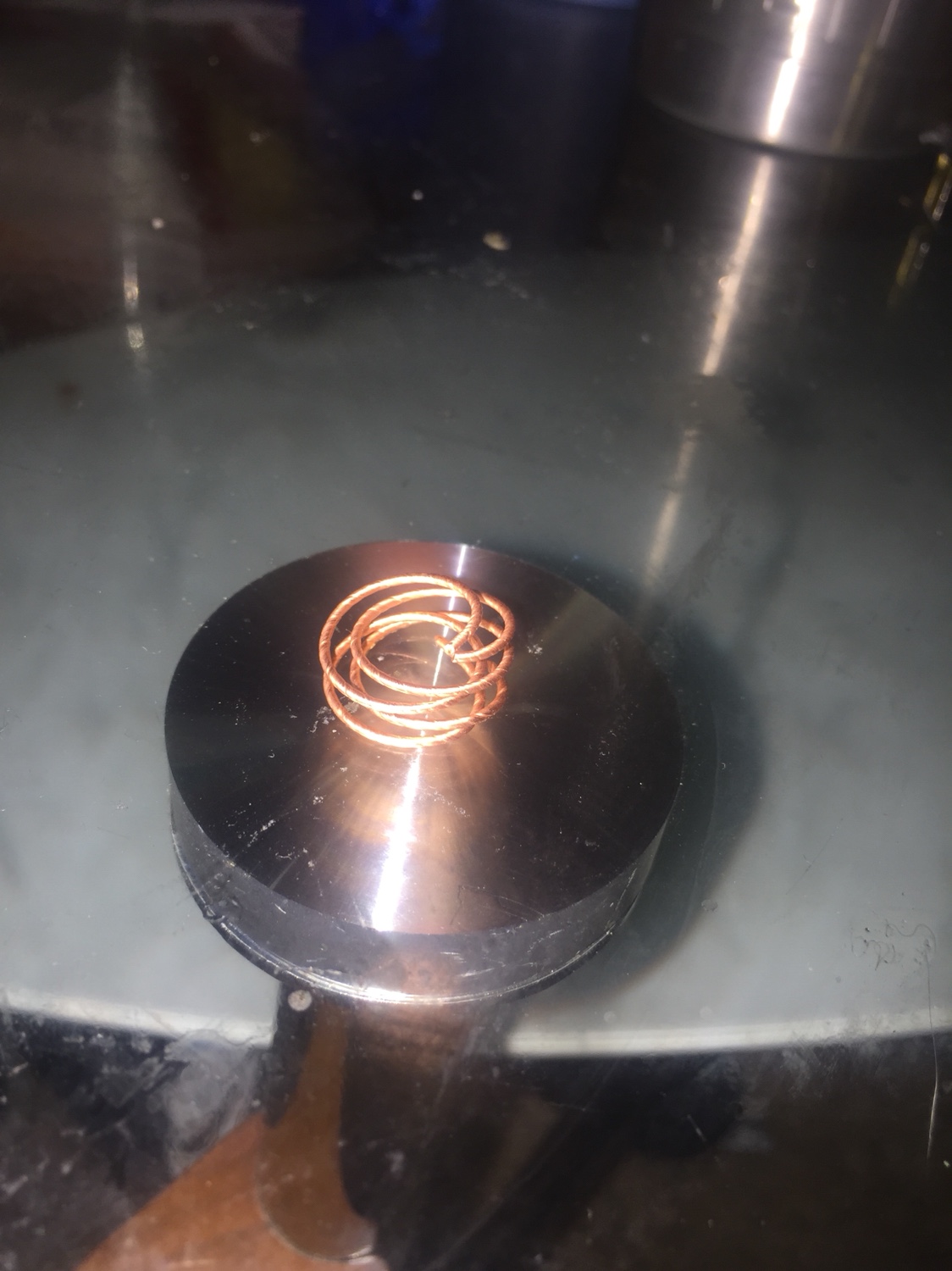

And this is where the spring (or opposing magnet) would need to be...looks to be an inch across with a half inch hole in the middle of it.

I’m preferring a quick solution I can take care of locally in some way, but if I have to order something and play the waiting game, so be it.

Thanks in advance!

How dare you incinerate that I don’t know how to use big words!

I’m not needing an exact replica of what I have and it doesn’t even have to be from a vape place...I work at a hardware store, but the only springs that would come close to working are these

But these contain Zinc and I’m not sure if the spring would generate enough heat to cause toxic elements to come out of it.

Here are some pics and measurements...if anyone knows of a nationwide store or a general idea of what type of store to look in, it would be greatly appreciated

Looks like a half inch across

That’s the disc portion of the button with the post the spring/magnet needs to fit around

And this is where the spring (or opposing magnet) would need to be...looks to be an inch across with a half inch hole in the middle of it.

I’m preferring a quick solution I can take care of locally in some way, but if I have to order something and play the waiting game, so be it.

Thanks in advance!

How dare you incinerate that I don’t know how to use big words!