Have any of you guys tried electroplating contacts that has had the original plating worn off from excessive cleaning? I have almost everything I need to set up the electroplating bath, just waiting on one more package to arrive. I just wanted to see if any of you have done this before, and how it turned out. I was considering maybe even plating a tube mod if the contacts worked out well.

Become a Patron!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Plated Contacts

- Thread starter Syythe

- Start date

I will take some before and afters for you guys. I got my fingers crossed for this project.I have no experience but anxious to see how it works out for you.

I used to work with some pretty caustic stuff in a couple different jobs. It doesn't bother me, just need to use proper PPE and some grey matter and it's all good.I hate messing with acid...have tried a jeweler...

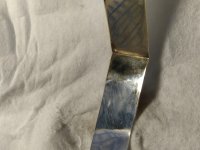

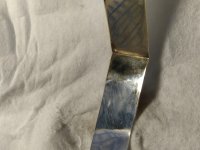

I cleaned and polished an old copper contact bar I had laying around to test if this silver plating set up would even work.

I set up a hinged lid mason jar and put the plating solution in it. I cut the end off an old 3v 200mah charger I had laying around, and soldered gator clips to the ends. Attach the neg side to the copper contact and the pos side to a .999 fine silver strip. Used my soldering 3rd hand tool to hold the copper contact in the solution and bent the end of the silver strip to hang on the side of the jar into the solution. Plugged it in and the submerged part of the silver strip turns a blackish brown, and the copper contact starts to bubble.

It only took a couple of minutes to see results. The contact now had a off-white powdery oxidation to it. I polished that off and under it was silver plated copper. IT WORKED!!!

The plating is a bit thin, but another dip for a while longer will take care of that. Then a proper polish and cleaning to make it look nice and neat. I am going to finish it all up tomorrow. I am really excited about this, I have a few things I want to try to do with this electroplating rig.

I set up a hinged lid mason jar and put the plating solution in it. I cut the end off an old 3v 200mah charger I had laying around, and soldered gator clips to the ends. Attach the neg side to the copper contact and the pos side to a .999 fine silver strip. Used my soldering 3rd hand tool to hold the copper contact in the solution and bent the end of the silver strip to hang on the side of the jar into the solution. Plugged it in and the submerged part of the silver strip turns a blackish brown, and the copper contact starts to bubble.

It only took a couple of minutes to see results. The contact now had a off-white powdery oxidation to it. I polished that off and under it was silver plated copper. IT WORKED!!!

The plating is a bit thin, but another dip for a while longer will take care of that. Then a proper polish and cleaning to make it look nice and neat. I am going to finish it all up tomorrow. I am really excited about this, I have a few things I want to try to do with this electroplating rig.

forget that i have an antique silver tea pot he can fix.A silver plated mod in the future. I have a mech tube I can donate for experimental purposes. Oh the possibilities?

HOW VERY CLEVER YOU ARE @Syythe

I have a tube I am considering doing. I am still kind of playing with it to find the best way to clean the metals so that the plating sticks the best it can. If I do a mod I want it to have the best chance to come out as perfect as I can get it.A silver plated mod in the future. I have a mech tube I can donate for experimental purposes. Oh the possibilities?

If anyone else wants to try this, they sell the pre-made solution to use. All you would need is a low power charging cable, and a glass jar. Here is a link to the stuff on amazon, it goes in and out of stock often (currently out of stock) but if you keep an eye on it you should see them restock soon.

Amazon.com: Bright Silver Electroplating Solution 1 Quart Jewelry Plating Bath Metal Pieces : Arts, Crafts & Sewing

Shop Krohn at the Amazon Arts, Crafts & Sewing store. Free Shipping on eligible items. Save on everyday low prices.

www.amazon.com

I just really like solving problems, and have a love for science. This problem let me play with stuff in a sciency way to find a way to fix it, so it just seemed really fun and entertaining to me. It just happened to work out this time, so that is a big bonus.You are a master vaper sir. I admire your knowledge and skill.

That's awesome. I worked in 2 different industrial chrome and nickel plating facilities when I was younger. Plated landing gear components for Boeing at one place, press tools for major auto manufacture at the other. Same concept only on a much larger scale. Always wanted to have my own small scale plating set up. Kudos my man. That looks like it could be a lot of fun.

Any tips on getting the metal super clean would be appreciated. Currently I polish it, give it an acetone bath for a few minutes, then wash it in distilled water in an ultra sonic cleaner. Then I let it air dry.That's awesome. I worked in 2 different industrial chrome and nickel plating facilities when I was younger. Plated landing gear components for Boeing at one place, press tools for major auto manufacture at the other. Same concept only on a much larger scale. Always wanted to have my own small scale plating set up. Kudos my man. That looks like it could be a lot of fun.

Pretty cool stuff. I don't fully get it but it's still really cool.If anyone else wants to try this, they sell the pre-made solution to use. All you would need is a low power charging cable, and a glass jar. Here is a link to the stuff on amazon, it goes in and out of stock often (currently out of stock) but if you keep an eye on it you should see them restock soon.

Amazon.com: Bright Silver Electroplating Solution 1 Quart Jewelry Plating Bath Metal Pieces : Arts, Crafts & Sewing

Shop Krohn at the Amazon Arts, Crafts & Sewing store. Free Shipping on eligible items. Save on everyday low prices.www.amazon.com

been reading about all this since i saw you doing it..Any tips on getting the metal super clean would be appreciated. Currently I polish it, give it an acetone bath for a few minutes, then wash it in distilled water in an ultra sonic cleaner. Then I let it air dry.

found this

Standard Guide for Cleaning Metals Prior to Electroplating

http://www.galvanizeit.com/uploads/resources/ASTM-B-322-yr.-99-R-14.pdf

there is a LOT out there about proper surface prep.

I know, there is an overwhelming amount of info on it. I have been reading a whole lot lately, since it is the key to getting a really good adhesion between the base metal and the plating metal. I appreciate the link, I will give it a good read through. A lot of the info I am seeing is that I will need to get a lightly corrosive solution to soak the parts in to add to what I already have been doing. Something like a consumer grade hydrochloric acid, and then further water it down.been reading about all this since i saw you doing it..

found this

Standard Guide for Cleaning Metals Prior to Electroplating

http://www.galvanizeit.com/uploads/resources/ASTM-B-322-yr.-99-R-14.pdf

there is a LOT out there about proper surface prep.

am keeping this link...I know, there is an overwhelming amount of info on it. I have been reading a whole lot lately, since it is the key to getting a really good adhesion between the base metal and the plating metal. I appreciate the link, I will give it a good read through. A lot of the info I am seeing is that I will need to get a lightly corrosive solution to soak the parts in to add to what I already have been doing. Something like a consumer grade hydrochloric acid, and then further water it down.

little light reading for sparkey to do so HE can re silver all my stuff....

seeeee how smart you can inspire me to be?

That one looks super comprehensive. Love it. There is a months worth of bathroom literature there for me to sort through, maybe more.am keeping this link...

little light reading for sparkey to do so HE can re silver all my stuff....

seeeee how smart you can inspire me to be?

This is very cool.