Become a Patron!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Post your builds

- Thread starter Vape_geek

- Start date

CrazyChef

Custom Hand Crafted Coils - PureCoils.com

VU Vendor

VU Donator

Platinum Contributor

Member For 4 Years

ECF Refugee

Don't. Those were a lot of coils you made.

I've been at this all day - staples, framed staple, aliens, flattened aliens, etc. I still have to package them all and get them ready to ship.

And I have to get up at 6:00 tomorrow morning for my day job.

I've been at this all day - staples, framed staple, aliens, flattened aliens, etc. I still have to package them all and get them ready to ship.

And I have to get up at 6:00 tomorrow morning for my day job.

Well since Ive checked about 3 times now that Im posting in the correct place Im going to rehash the post, I apologize again for that Chef.

I thought it would be a pretty cool idea to see how many coils everyone here has made in one day, like a buildoff that was taken a day in the past or something similar. Seeing all the coils Chef posted reminded me of around 3 weeks ago when I had a day where I built coils for 10 hours straight. My hands have tendinitis and they were swollen for 2 whole days like balloons. I think the total amount of individual coils was 68 but Im unsure, I made a pile of coils at first then I threw them into a ziplock bag and made another pile, I sorted the second pile and stored them into a Walmart organizer bin

They are all different types of coils ranging from Tri Core Staggereds, Fused Claptons, Aliens, Alien Framed Staples, and others...I actually think this is the reason I feel my drills speed has decreased....I think its dying due to this one day of it spinning almost nonstop...(Im glad I work at home at my own pace, I give you additional respect and credit for actually working the next day Chef

I thought it would be a pretty cool idea to see how many coils everyone here has made in one day, like a buildoff that was taken a day in the past or something similar. Seeing all the coils Chef posted reminded me of around 3 weeks ago when I had a day where I built coils for 10 hours straight. My hands have tendinitis and they were swollen for 2 whole days like balloons. I think the total amount of individual coils was 68 but Im unsure, I made a pile of coils at first then I threw them into a ziplock bag and made another pile, I sorted the second pile and stored them into a Walmart organizer bin

They are all different types of coils ranging from Tri Core Staggereds, Fused Claptons, Aliens, Alien Framed Staples, and others...I actually think this is the reason I feel my drills speed has decreased....I think its dying due to this one day of it spinning almost nonstop...(Im glad I work at home at my own pace, I give you additional respect and credit for actually working the next day Chef

Last edited:

CrazyChef

Custom Hand Crafted Coils - PureCoils.com

VU Vendor

VU Donator

Platinum Contributor

Member For 4 Years

ECF Refugee

That's why I have extras - I can't be without one. 2 cordless and 3 corded...I actually think this is the reason I feel my drills speed has decreased...

At least my boss lets me take time off to do the coil business. I'm down to working Monday, Wednesday and Friday only. This way I can keep up with my builds. It's also the reason why I don't have any time left for fun builds.I give you additional respect and credit for also for actually working the next day Chef

I really want a nice Brushless drill, Corded or not with slightly higher RPM speeds and a better trigger. The drill I use now is wired to the charger because my son broke off the plug end on the charger, so I wired the plug to the female connections wires and Im actually glad I did that as I usually dont remember how long drill batteries last off the charger until I take it somewhere...I just dont have the money for it right now...Ive been trading coils for juice because Im basically broke for the next 3 weeks and Im terrified that I wont have enough before August...That's why I have extras - I can't be without one. 2 cordless and 3 corded.

At least my boss lets me take time off to do the coil business. I'm down to working Monday, Wednesday and Friday only. This way I can keep up with my builds. It's also the reason why I don't have any time left for fun builds.

Thats pretty amazing that your boss is that cool!

Last edited:

CTFX

Platinum Contributor

Member For 4 Years

Member For 3 Years

Member For 2 Years

Member For 1 Year

Heres what I made today. A shit ton of fused claptons (SS and kanthal), a bunch of staggered claptons, a couple framed staples, and a few regular staples.

Man you guys are lucky, I only get 2-3 hours a week to build! I'd kill for a whole day of pissing around with wire.

Man you guys are lucky, I only get 2-3 hours a week to build! I'd kill for a whole day of pissing around with wire.

I built all of those in about 2 hours. The fused claptons take no time at all, the staggered claptons take a little longer, but its the staples that take the longest. You can knock out a 2 or 3 foot section of fused clapton wire in 15 minutes or so.

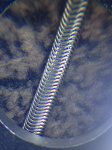

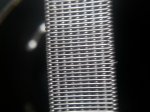

Been awhile. Nothing fancy but it's the hottest build I've had on my HoG v2, quad 24g Mad Rabbit 14 wrap 3.6id. .16 ohm.

View attachment 50775 View attachment 50776

Shit balls, a 0.16 set up on a series mod? Thats borderline crazy lol. Thats pushing 450 watts with charged batteries.

Yea I can pump out a couple sets of fc's in a few mins but the more complicated builds that I like I only get to do one set a week since it takes most of my time.I built all of those in about 2 hours. The fused claptons take no time at all, the staggered claptons take a little longer, but its the staples that take the longest. You can knock out a 2 or 3 foot section of fused clapton wire in 15 minutes or so.

Shit balls, a 0.16 set up on a series mod? Thats borderline crazy lol. Thats pushing 450 watts with charged batteries.

43 amps 298 watts

Word. Ive been using mine for the last hour or 2 (first time in a week +) and its at around a .45-.5. Pretty nice vape and the lowest I like to go on my series mods. Theyre the Aliens I got from Chef. I like having some higher mass coils in the series mods.

you have to remember the HoG v2 is 2s2p and you also have a volt meter. Most of my builds for it are massive. Things like 4mm 8 wrap 3x26n80/36n80 aliens or 10 wrap 20n80 4mm coils. The HoG v2 shines with a 30mm atties. The coils from Chef are probably 3x30n80/40n80, and those are great coils in a 22mm atty on NC. (I run them myself)

Built these little guys yesterday, install on the bambino was a bitch but not a bad vape on my mini volt.

32/42 micro fused claptons ~.6 ohm. Theyre ridiculously small.

32/42 micro fused claptons ~.6 ohm. Theyre ridiculously small.

had a bit of a flood the other day from upstairs at my place (condo) put an end to what was going to be an all day build day before i even got started. finally got a little time tonight to at least make a few coils for the dude who gave me most of this wire. made about two feet of alien and (my first ever proper) framed staples. progress.

iSubOhm

Silver Contributor

Member For 4 Years

Member For 3 Years

Member For 2 Years

Member For 1 Year

Member For 5 Years

I just bought that case! I got a new drill as a Christmas gift, but it has a hole in the chuck even when tightened down.. makes it a little tough to use because my core wires can kind of bounce around.. I bend the end going into the chuck into an L shape to grab it from the side. Only way it will work.. I need to look for a new one soon and new setup for my swivels.. I think it's kinking because I'm putting tension at a slight angle instead of completely parallel. Does this matter a lot?Heres what I made today. A shit ton of fused claptons (SS and kanthal), a bunch of staggered claptons, a couple framed staples, and a few regular staples.

Instagram: @ohmmage

You like that cotton Chef? I have almost 200ft of PIMA and I cant stand it, you can have it if you want it...

I was just going to ask what material that is. Doesn't look like cotton to me... looks synthetic. What brand of cotton is that?

Scratch that, after reading the next page, I found out that it is the silk stuff. Where are you getting that from? I am finally making the move from japanese cotton pads to Cotton Bacon v2.

Last edited:

So I finally pulled off a Corrugated Build without the Ribbon folding or anything...My crimping was too far apart before and this time I used much smaller teeth and Im guessing it gave it more ridgity over the bends. It came out okay and Im pretty happy with it...

Specs: 6 x .3R/28KA1/38N80/42N80 (4 Wraps/3mm ID)

Specs: 6 x .3R/28KA1/38N80/42N80 (4 Wraps/3mm ID)

Is that the right one raymo?

Looks right, this is the exact page I got mine from: LINKIs that the right one raymo?

5 bucks cheaper. On it....Thx MrG

Pay pal came up with a total of $11.20, even better - scratch that, looks like that is in pounds or euros.

Pay pal came up with a total of $11.20, even better - scratch that, looks like that is in pounds or euros.

Last edited:

I just bought that case! I got a new drill as a Christmas gift, but it has a hole in the chuck even when tightened down.. makes it a little tough to use because my core wires can kind of bounce around.. I bend the end going into the chuck into an L shape to grab it from the side. Only way it will work.. I need to look for a new one soon and new setup for my swivels.. I think it's kinking because

I'm putting tension at a slight angle instead of completely parallel. Does this matter a lot?

Instagram: @ohmmage

I just use an eye hook chucked in the drill and tie one end of my core wires to that. Works well for simple stuff like dual or triple core wire, but for staples and stuff it's too hard to tie them to the hook evenly without twisting

iSubOhm

Silver Contributor

Member For 4 Years

Member For 3 Years

Member For 2 Years

Member For 1 Year

Member For 5 Years

Well what I meant was the spot I have my swivels mounted is significantly lower than the chuck of the drill, so the core wire is pointing down from the chuck of the drill and I'm feeling this might be why when I try to use it to clapton certain coils it kinks and twists my wire. Specifically staple wiresI just use an eye hook chucked in the drill and tie one end of my core wires to that. Works well for simple stuff like dual or triple core wire, but for staples and stuff it's too hard to tie them to the hook evenly without twisting

I think I need the core wire to be perfectly straight from swivel to chuck to ensure it won't kink while spinning. Because one set is tested at 200 lbs and the others are tested at 288.4kg.. So there's no way I have too much tension lol

I think I need the core wire to be perfectly straight from swivel to chuck to ensure it won't kink while spinning. Because one set is tested at 200 lbs and the others are tested at 288.4kg.. So there's no way I have too much tension lol Instagram: @ohmmage

Mine are rated for 417lbs each and I have 6 of them wired up...they still bind if not lubed up or if I pull too hard on the drill, they just wont break if you pull to that weight. Keep it completely parallel and flat or your stressing it more then needed.Well what I meant was the spot I have my swivels mounted is significantly lower than the chuck of the drill, so the core wire is pointing down from the chuck of the drill and I'm feeling this might be why when I try to use it to clapton certain coils it kinks and twists my wire. Specifically staple wiresI think I need the core wire to be perfectly straight from swivel to chuck to ensure it won't kink while spinning. Because one set is tested at 200 lbs and the others are tested at 288.4kg.. So there's no way I have too much tension lol

Instagram: @ohmmage

So I finally pulled off a Corrugated Build without the Ribbon folding or anything...My crimping was too far apart before and this time I used much smaller teeth and Im guessing it gave it more ridgity over the bends. It came out okay and Im pretty happy with it...

Specs: 6 x .3R/28KA1/38N80/42N80 (4 Wraps/3mm ID)

View attachment 50818 View attachment 50816 View attachment 50813 View attachment 50815 View attachment 50817 View attachment 50814

Damn Ray that looks so sharp! I knew you would get it CONGRATZ! How does it vape?

I dont know I have a crazier one in the Works right now...I need to get some wax and use that to keep it all together while Im adding to it, wrapping wire or ribbon around it can mess it up 9/10 times in my fingers..Damn Ray that looks so sharp! I knew you would get it CONGRATZ! How does it vape?

I wanted to try the Corrugated SSFC with Larger Gauges and Wider Ribbon Wire...Its not as tight or clean as I thought it would turn out, I thought more Ribbon would help reinforce the form of it but it does not. Im not going to try this again with .6 as I think thats the number one reason it is barely keeping form, if I used .3/.4 then it would of formed much better and kept it afterwards.

SPECS: 12 X .6R/24N80/36N80/40N80

SPECS: 12 X .6R/24N80/36N80/40N80

Not so sure that would be very good for vaping, but would make a cool looking ring or something. People who like jewelry would probably go apeshit and cough up some big bucks for those, perhaps in lower gauges to make them bigger. I don't wear any jewelry but would actually consider something like that.

What's up buddy, been a while, hope all is well. Haven't had a lot of time lately so whatever free time I did have I've been putting into building, sadly haven't had time for the forum... anyways.... IDK why but I've been in a bit of a stagger slump lately. Went from making beautiful staggered variations to barely being able to spit out a standard single core stagger without having the loop jump out of place and starting to Clapton rather then stagger -_-...@BrattVapes Showed me a pic on instagram about a build to see if I could do it...I was going to put it off until tomorrow but I had some free time and tried it....had this pumped out in less then 20 minutes start to finish!

10 x .6R/24N80/32N80/38N80 Half Staggered Staple?

View attachment 49811 View attachment 49812 View attachment 49813 View attachment 49814 View attachment 49815 View attachment 49816

My question to you is this.... when you stagger ribbon stacks, does your loop keep breaking from the edge of the ribbon? Either way, any tips with any of this would be amazing as its getting deeply frustrating! I hate when I'm in a building slump!

OH, one more thing! I know this will be the third time I'm asking but I lost the little picture u made me last time showing me how you wrap the loop around 3 wraps or something? Any help would be appreciated brother

I stopped doing it that way and started using the Spool Tamers to stagger with, its much easier and faster..No the Ribbon doesnt cut the wrap but it does twist alot and I have to untwist it before using it.What's up buddy, been a while, hope all is well. Haven't had a lot of time lately so whatever free time I did have I've been putting into building, sadly haven't had time for the forum... anyways.... IDK why but I've been in a bit of a stagger slump lately. Went from making beautiful staggered variations to barely being able to spit out a standard single core stagger without having the loop jump out of place and starting to Clapton rather then stagger -_-...

My question to you is this.... when you stagger ribbon stacks, does your loop keep breaking from the edge of the ribbon? Either way, any tips with any of this would be amazing as its getting deeply frustrating! I hate when I'm in a building slump!

OH, one more thing! I know this will be the third time I'm asking but I lost the little picture u made me last time showing me how you wrap the loop around 3 wraps or something? Any help would be appreciated brother

I dont have the pic on my pc but its somewhere in the thread...

This is how I stagger everything now:

You don't stagger to a specific awg?I stopped doing it that way and started using the Spool Tamers to stagger with, its much easier and faster..No the Ribbon doesnt cut the wrap but it does twist alot and I have to untwist it before using it.

I dont have the pic on my pc but its somewhere in the thread...

This is how I stagger everything now:

View attachment 50908 View attachment 50909 View attachment 50910 View attachment 50911

Sent from my HTC One_M8 using Tapatalk

And when I stagger a stack of ribbon my loop always snaps... I go threw like 5 loops each length... and IDK what it is but all week I couldn't put together a stagger if my life depended on its... I'm going to see if I got a few pics of a few variations before my little slump,I stopped doing it that way and started using the Spool Tamers to stagger with, its much easier and faster..No the Ribbon doesnt cut the wrap but it does twist alot and I have to untwist it before using it.

I dont have the pic on my pc but its somewhere in the thread...

This is how I stagger everything now:

View attachment 50908 View attachment 50909 View attachment 50910 View attachment 50911

Sent from my HTC One_M8 using Tapatalk

Nope, I adjust to what I feel is right and then keep the spool fom moving while it travels down the wire...You don't stagger to a specific awg?

Sent from my HTC One_M8 using Tapatalk

I believe this is 10x .5k/28g frames/ 36g stagger + fuse

4x .5k 36g Stagger

Framed 2) 3x .5k

Framed again. 28g

36g fused

9x .5k 34g stagger

28g frames with 36g fuse

My favorite so far (this the first go at this variation, need to take new pics!)

4x .5k half framed with 28g all with 36g stagger

Next to this is the same just naked and fused together with 36g

Sent from my HTC One_M8 using Tapatalk

4x .5k 36g Stagger

Framed 2) 3x .5k

Framed again. 28g

36g fused

9x .5k 34g stagger

28g frames with 36g fuse

My favorite so far (this the first go at this variation, need to take new pics!)

4x .5k half framed with 28g all with 36g stagger

Next to this is the same just naked and fused together with 36g

Sent from my HTC One_M8 using Tapatalk

Ahh that would drive me nuts not having the exact fit for the fuse, I have ocd when it comes to that shit. I do gotta get some spool tamers, u get yours on eBay? I can't find them in any craft store b&ms .Nope, I adjust to what I feel is right and then keep the spool fom moving while it travels down the wire...

Sent from my HTC One_M8 using Tapatalk

A little piece of tape will protect those elastic bands. I wonder if cutting a guide groove in the tamers' plastic with a mini v file would work to keep the spool correctly oriented. I see your wire is doing that on it's own.

Yup yup, search Beadalon Spool Tamers on Ebay. They have a 25 Pack for $15Ahh that would drive me nuts not having the exact fit for the fuse, I have ocd when it comes to that shit. I do gotta get some spool tamers, u get yours on eBay? I can't find them in any craft store b&ms .

Sent from my HTC One_M8 using Tapatalk

Im pretty good at getting the size right for what I need...check out how tight the fitment is when I want it tight:

and when I want it loose...

Yeah looks good. What made you start doing it this way?Yup yup, search Beadalon Spool Tamers on Ebay. They have a 25 Pack for $15

Im pretty good at getting the size right for what I need...check out how tight the fitment is when I want it tight:

View attachment 50928

and when I want it loose...

View attachment 50929

Sent from my HTC One_M8 using Tapatalk

I bought the tamers for keeping the spools together and someone said you can clapton with it, when I was trying to find out which direction to clapton I saw it will stagger the wrap if turned certain ways....since then Ive used it for some crazy shit, I did a 9 Core Staggered Fused clapton with it...I wear it as a ring as the wires I used were too big but Ive done a bunch of quad core and tri cores and they work great.Yeah looks good. What made you start doing it this way?

Sent from my HTC One_M8 using Tapatalk

That ring is fucking awesome. And wow I didn't think you'd get 9 cores equal space.... good shit man, u save a butt load of time this way yeah?I bought the tamers for keeping the spools together and someone said you can clapton with it, when I was trying to find out which direction to clapton I saw it will stagger the wrap if turned certain ways....since then Ive used it for some crazy shit, I did a 9 Core Staggered Fused clapton with it...I wear it as a ring as the wires I used were too big but Ive done a bunch of quad core and tri cores and they work great.

View attachment 50933 View attachment 50931 View attachment 50932 View attachment 50930

Sent from my HTC One_M8 using Tapatalk

You could say thatThat ring is fucking awesome. And wow I didn't think you'd get 9 cores equal space.... good shit man, u save a butt load of time this way yeah?

Sent from my HTC One_M8 using Tapatalk