Hey Vape Dudes & Dudettes-

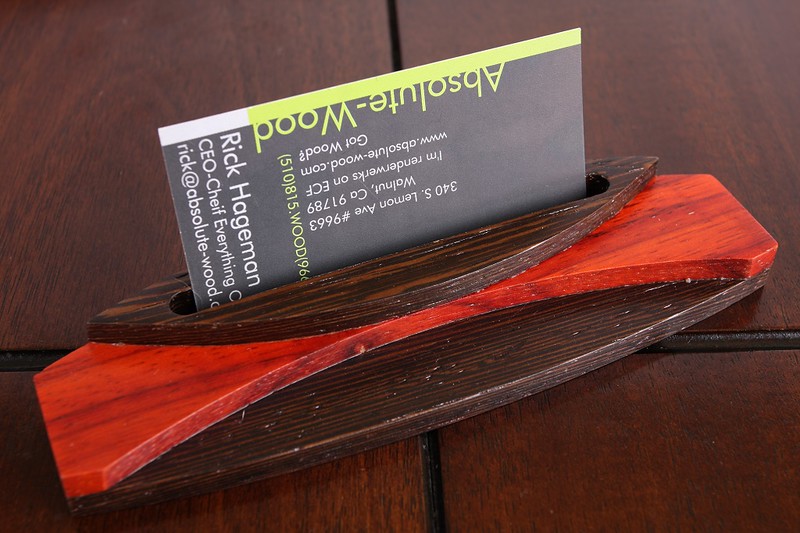

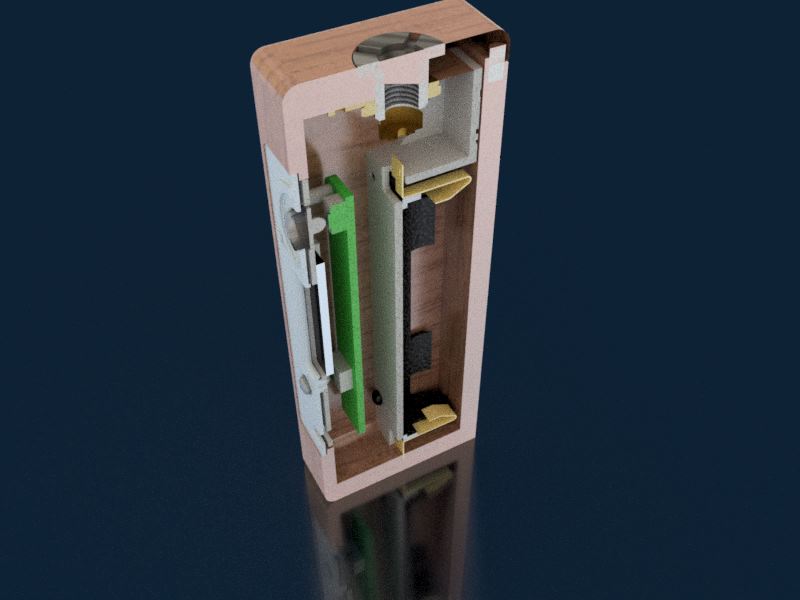

This thread will be for talking about what's happening in the shop. Special projects, experiments, possible new products, things you might like to see designed, etc...

To start, I'll highlight some work on a large juice bar holder for a B&M I'm currently working on:

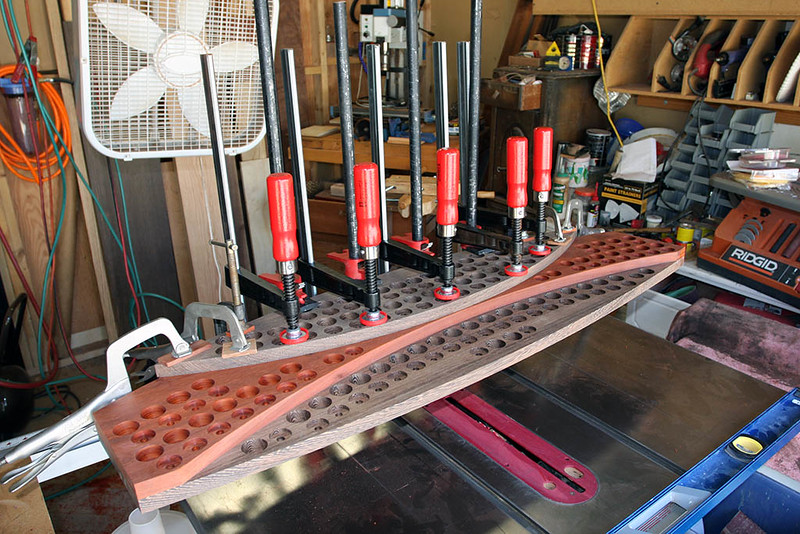

Mainly been lost in the shop working on the "major wood" holder - it's getting close:

Each piece has it's front edge hand sanded to it's finished profile. If you look closely, you can see the paper template on the far side of the board. This is a single piece of African Padauk - 12" x 45". Made a custom radius Maple sandpaper block to hand sand both the convex and concave curves of all pieces.

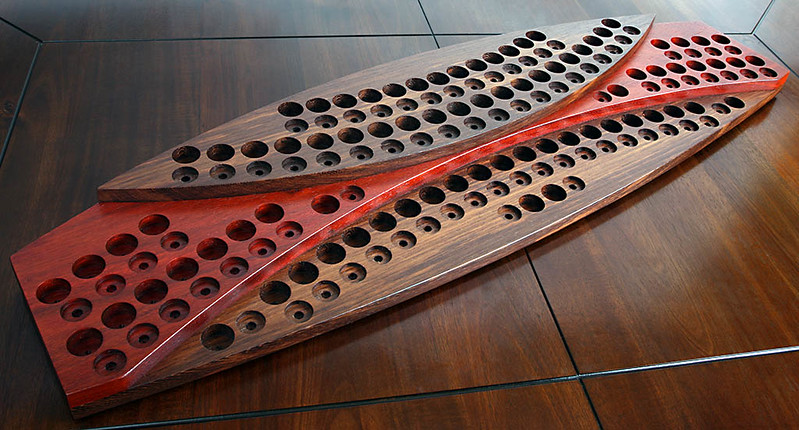

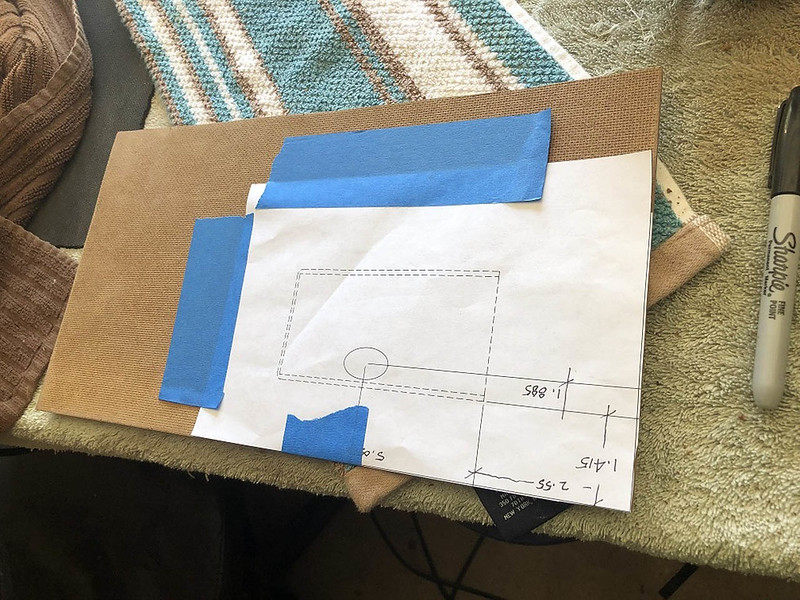

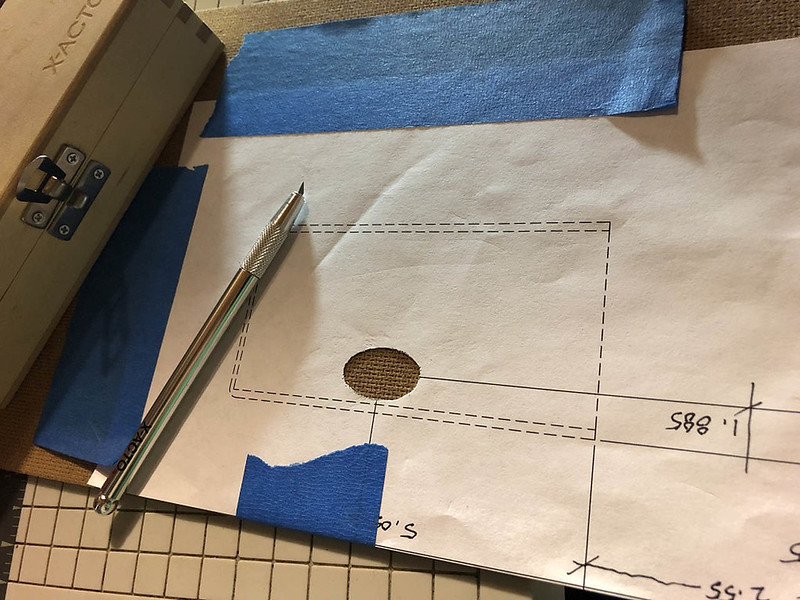

These are the three steps of the holder. They have been machine sanded almost to finished size. The hole location templates were taped to the pieces after hand sanding of the front edges. I hand punch the center of each hole before the holes are created.

Boring the juice bottle holes on the top step. All steps are drilled, then the tool is changed to drill the tank holes.

Boring the tank holes on the bottom (base) of the holder. The tool drills both the main hole and the smaller hole for the tank connector at the same time. The juice bottle holes have previously been drilled.

Finally! What a boring job... Sorry, couldn't resist. That's 160 holes!

That's 160 holes!  Took hours...

Took hours...

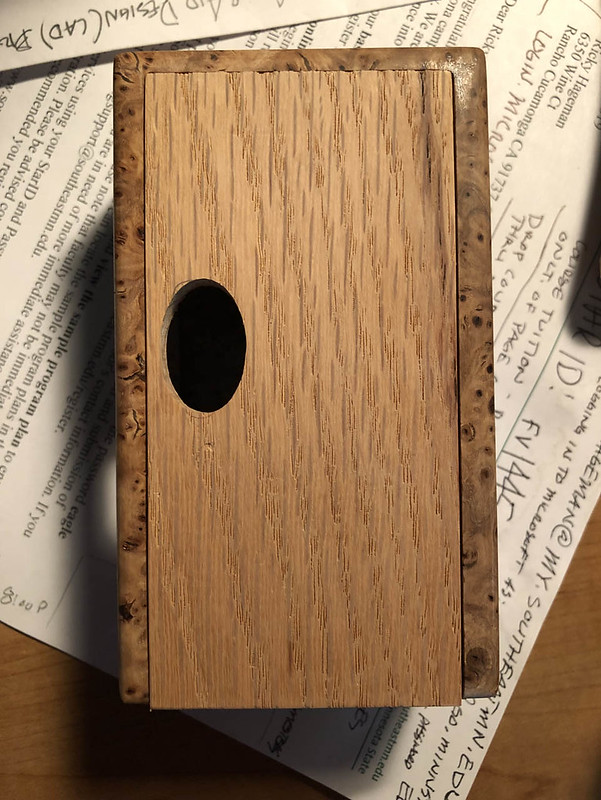

These pieces are just sitting on one another. The bottom is sanded to exact size - the back edges of the second and top step have been left a little oversize. The bottom two steps will be glued, then the excess material from the second step will be trimmed off to exactly match the profile of the bottom piece. Then the process will be repeated for the top piece.

Back to the shop!

Rick

This thread will be for talking about what's happening in the shop. Special projects, experiments, possible new products, things you might like to see designed, etc...

To start, I'll highlight some work on a large juice bar holder for a B&M I'm currently working on:

Mainly been lost in the shop working on the "major wood" holder - it's getting close:

Each piece has it's front edge hand sanded to it's finished profile. If you look closely, you can see the paper template on the far side of the board. This is a single piece of African Padauk - 12" x 45". Made a custom radius Maple sandpaper block to hand sand both the convex and concave curves of all pieces.

These are the three steps of the holder. They have been machine sanded almost to finished size. The hole location templates were taped to the pieces after hand sanding of the front edges. I hand punch the center of each hole before the holes are created.

Boring the juice bottle holes on the top step. All steps are drilled, then the tool is changed to drill the tank holes.

Boring the tank holes on the bottom (base) of the holder. The tool drills both the main hole and the smaller hole for the tank connector at the same time. The juice bottle holes have previously been drilled.

Finally! What a boring job... Sorry, couldn't resist.

These pieces are just sitting on one another. The bottom is sanded to exact size - the back edges of the second and top step have been left a little oversize. The bottom two steps will be glued, then the excess material from the second step will be trimmed off to exactly match the profile of the bottom piece. Then the process will be repeated for the top piece.

Back to the shop!

Rick