As part of our quest to be the ULTIMATE tool for vapers, we are continuously looking to improve VaporSuite, and we are re-developing the coil design module completely. We would like to get your input during the planning stage to ensure that we will end up with a tool that is THE BEST, and will appreciate your feedback on the items below.

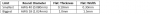

1. Coil Types

Notes:

(Q1b) Set spacing as x times diameter (width for flat) or precise mm?

2. Wire Size Range

(Q2) Is there any need to go bigger or smaller?

3. Wire Precision

Round: 2 decimals = 1% or better; 3 decimals = 0.1% or better

From a practical point, I believe 1% (2 decimals) is sufficient for coil calculations – other tolerances, etc. have a much bigger influence on the calculated resistance (can easily be 5% or more).

(Q3a) Is there any reason to be better than 1% (2 decimals)?

Flat (Ribbon): All ribbon wire I could find have 1 decimal precision (e.g. 0.5 X 0.1).

(Q3b) Any reason to use 2 decimals (e.g. 0.55 X 0.13)?

4. Coil Diameter (Pin Size)

Min = 1.0; Max = 5.0.

(Q4) Any reason to go smaller or bigger?

5. Number of Wraps

Min = 3; Max = 13 (13.5 for same side legs).

(Q5) Any reason to go lower or higher?

6. Ohm Target

Min = 0.10 Ohm; Max = 3.0 Ohm. Note: This is only for setting a target resistance if that option is selected. The actual calculated value will be any value based on the parameters – it is not limited at all.

(Q6) Any reason to go lower or higher?

7. Wrap Spacing

Theoretical calculations show that the spacing between wraps of a coil has a very small effect (< 1% if the spacing is 3 X wire diameter.

(Q7) Is it worth adding this?

8. TCR for mixed materials

I plan to add a calculation to give an approximate TCR value for mixed materials, so if e.g. you make a coil with one strand of 316L and another of Kanthal A1, it will give a TCR value that should be a good starting point for temp control with this coil.

(Q8) Will this be a valuable addition?

9. Multiple Coil Configurations

This will be to calculate the effective resistance (and other parameters) if multiple coils are used in the Atomizer.

Propose to select multiple parallel coils (1 to 8 Coils) for different set-ups.

(Q9a) Is there any need to include series coils or a combination of series and parallel connected coils?

(Q9b) Is there any need for more than 8 coils in parallel?

(Q10) Any other requirements or things you would like to have in a coil design calculator?

1. Coil Types

Notes:

- All Claptons: allow for spacing of outer wrap - select 0,1,2, or 3 times diameter for outer wrap.

- All strands: can be round or flat.

(Q1b) Set spacing as x times diameter (width for flat) or precise mm?

2. Wire Size Range

(Q2) Is there any need to go bigger or smaller?

3. Wire Precision

Round: 2 decimals = 1% or better; 3 decimals = 0.1% or better

From a practical point, I believe 1% (2 decimals) is sufficient for coil calculations – other tolerances, etc. have a much bigger influence on the calculated resistance (can easily be 5% or more).

(Q3a) Is there any reason to be better than 1% (2 decimals)?

Flat (Ribbon): All ribbon wire I could find have 1 decimal precision (e.g. 0.5 X 0.1).

(Q3b) Any reason to use 2 decimals (e.g. 0.55 X 0.13)?

4. Coil Diameter (Pin Size)

Min = 1.0; Max = 5.0.

(Q4) Any reason to go smaller or bigger?

5. Number of Wraps

Min = 3; Max = 13 (13.5 for same side legs).

(Q5) Any reason to go lower or higher?

6. Ohm Target

Min = 0.10 Ohm; Max = 3.0 Ohm. Note: This is only for setting a target resistance if that option is selected. The actual calculated value will be any value based on the parameters – it is not limited at all.

(Q6) Any reason to go lower or higher?

7. Wrap Spacing

Theoretical calculations show that the spacing between wraps of a coil has a very small effect (< 1% if the spacing is 3 X wire diameter.

(Q7) Is it worth adding this?

8. TCR for mixed materials

I plan to add a calculation to give an approximate TCR value for mixed materials, so if e.g. you make a coil with one strand of 316L and another of Kanthal A1, it will give a TCR value that should be a good starting point for temp control with this coil.

(Q8) Will this be a valuable addition?

9. Multiple Coil Configurations

This will be to calculate the effective resistance (and other parameters) if multiple coils are used in the Atomizer.

Propose to select multiple parallel coils (1 to 8 Coils) for different set-ups.

(Q9a) Is there any need to include series coils or a combination of series and parallel connected coils?

(Q9b) Is there any need for more than 8 coils in parallel?

(Q10) Any other requirements or things you would like to have in a coil design calculator?

Last edited: