this is awesome!

Become a Patron!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Post your builds

- Thread starter Vape_geek

- Start date

And by the way... how did These smurf Aliens perform?Very good, alot of people have forgotten that build...it really shocks me that I did it in the past, theres no way in hell I would even think of attempting it again!

It was 50g Alien on a single ply of .3 Ribbon....

Everything comes with practice though, there are many from this forum that have grown to the same level in a matter of weeks, which blows me way....Ive been building for almost 2 years+ and its taking me this long to get whee I am...but then again there wasnt much help, no videos back then...and no one liked to share tips or help really, this forum was the exception and I owe most of what Ive learned to all the great people in this thread.

But i think you are perfectly right, i got a lot of Inspiration from you and the other Great builders in this Thread, and a lot of courage! I know everybody is struggling sometimes but the More you try The more offen you will Succed and get Motivation for the Next Step. Just remember Chef's historic First buid! And how far has he come.

And you Tried to defend your simpel Fused claptons against the conplex builds loooong Time ago

Almost forgot.... Tried my Next Step Today !! Worked further at my Helix staples and wanted to try corrugation. Since i got no crimper, but hey i Build my own coils i can Build it myself Not the prettiest one but works great.

So First attempt Had this specs

2x 30 GA Twisted, 6ply Ribbon (2 corrugated in the middle) and 36GA Fuse. All N80. 5 Wraps @ 3mm should Ohm at 0.1 as Dual coil. Wire was Perfect but fucked it up a litte while coiling. Man i Used a Vice and Nylon pliers but These suckers are a bitch to coil up.

Encouraded by this Build i Went a Step further and i just dont know if they have a Special Name ?

Okay for the Core i Had 4 Ply 0.3 ribbon space claptoned with 42GA, two single strands 0.3 corrugated, 4 ply 0.3 an der Twisted 32GA as Frames, so 10 ply of 0.3 in total.

Double Fused with 36GA to have more Support for Coling.

Love the result and am a Bit Proud Since this is my Most complex Build so far!

Coiled it 4 wraps 3mm would be around 0.07 Ohms Dual what is too low for me. When i want a Single coil Next Time i will usw one of These Babys.

So First attempt Had this specs

2x 30 GA Twisted, 6ply Ribbon (2 corrugated in the middle) and 36GA Fuse. All N80. 5 Wraps @ 3mm should Ohm at 0.1 as Dual coil. Wire was Perfect but fucked it up a litte while coiling. Man i Used a Vice and Nylon pliers but These suckers are a bitch to coil up.

Encouraded by this Build i Went a Step further and i just dont know if they have a Special Name ?

Okay for the Core i Had 4 Ply 0.3 ribbon space claptoned with 42GA, two single strands 0.3 corrugated, 4 ply 0.3 an der Twisted 32GA as Frames, so 10 ply of 0.3 in total.

Double Fused with 36GA to have more Support for Coling.

Love the result and am a Bit Proud Since this is my Most complex Build so far!

Coiled it 4 wraps 3mm would be around 0.07 Ohms Dual what is too low for me. When i want a Single coil Next Time i will usw one of These Babys.

I have only been building for 2 months but in my experience the greater surface area the more flavor. That being said how can the ribbon wrapped multicore builds beat fine wire multicore claptons? Im not trying to be antagonistic just want to learn. Talk about surface area this set of zipper claptons i made a month ago have over 50' of wire on the pair. No exageration. They are 30/40g N80Some simple builds i did in my objective to chase top flavor.

View attachment 78061

View attachment 78062

View attachment 78063 View attachment 78064

View attachment 78065 View attachment 78067

//uploads.tapatalk-cdn.com/20170328/5457b3cce3923beb97851a934f138cd3.jpg[/IMG

Sent from my SM-G920V using Tapatalk

Cool tool! Bottle caps?Almost forgot.... Tried my Next Step Today !! Worked further at my Helix staples and wanted to try corrugation. Since i got no crimper, but hey i Build my own coils i can Build it myself Not the prettiest one but works great.

View attachment 78088

So First attempt Had this specs

2x 30 GA Twisted, 6ply Ribbon (2 corrugated in the middle) and 36GA Fuse. All N80. 5 Wraps @ 3mm should Ohm at 0.1 as Dual coil. Wire was Perfect but fucked it up a litte while coiling. Man i Used a Vice and Nylon pliers but These suckers are a bitch to coil up.

View attachment 78086

Encouraded by this Build i Went a Step further and i just dont know if they have a Special Name ?

Okay for the Core i Had 4 Ply 0.3 ribbon space claptoned with 42GA, two single strands 0.3 corrugated, 4 ply 0.3 an der Twisted 32GA as Frames, so 10 ply of 0.3 in total.

Double Fused with 36GA to have more Support for Coling.

Love the result and am a Bit Proud Since this is my Most complex Build so far!

Coiled it 4 wraps 3mm would be around 0.07 Ohms Dual what is too low for me. When i want a Single coil Next Time i will usw one of These Babys.

View attachment 78084

View attachment 78085

Sent from my SM-G920V using Tapatalk

Nice micro Clapton zippers, very clean and colored beautiful !I have only been building for 2 months but in my experience the greater surface area the more flavor. That being said how can the ribbon wrapped multicore builds beat fine wire multicore claptons? Im not trying to be antagonistic just want to learn. Talk about surface area this set of zipper claptons i made a month ago have over 50' of wire on the pair. No exageration. They are 30/40g N80

//uploads.tapatalk-cdn.com/20170328/5457b3cce3923beb97851a934f138cd3.jpg[/IMG

Sent from my SM-G920V using Tapatalk

So in some cases you are right, more surface is sometimes more flavorful but not in any cases.

Every coil build has its own properties, and I was hunting for more and more surface area. But in my opinion (!!) some builds with very large surface area will loose their advantage very fast, when they gunk up and the tiny wraps will totally disappear because they are lost in juice caramelization.

So why do people say aliens have better flavour as fused claptons but the only difference is the wrap? Well I think it's the wicking properties and the wrap leaves way more space for the vape to exhaust.

I will give you an example. I LOVE builds with staples since the day I tried them. The framed staple was my favourite. But I had to dryburn it every two days because the wrap gunked up and when I fired them without topcap and saw the vape flowing out at very few areas where there was little gunk.

When I tried the staple helix that has less surface area I was stunned how much better the vape was and it lasts for days if not a week without loosing flavour.

I guess this build offers so much holes beneath the twisted wire and the ribbon for the juice to wick in and the vape to exhaust out what explains the advantage.

So in conclusion there are way more factors like ramp up, temperature, wicking and durability of the coil and for sure many more factors that influence flavour.

Thank you! I dont have any experience with helix but i think all your other observations are dead on! The framed staples ive built ar unreal for only a couple days when i use sweet juice then they carbon & gunk up and have i to clean em. Aliens have been all around great for me and dont need to be cleaned so often. So its not just juice holding surface area but wicking properties too, and the optimal heat for each individual juice must be a factor too rite? Btw the downside to those micro zippers is they pop and spit like crazy! Have you noticed this as well?Nice micro Clapton zippers, very clean and colored beautiful !

So in some cases you are right, more surface is sometimes more flavorful but not in any cases.

Every coil build has its own properties, and I was hunting for more and more surface area. But in my opinion (!!) some builds with very large surface area will loose their advantage very fast, when they gunk up and the tiny wraps will totally disappear because they are lost in juice caramelization.

So why do people say aliens have better flavour as fused claptons but the only difference is the wrap? Well I think it's the wicking properties and the wrap leaves way more space for the vape to exhaust.

I will give you an example. I LOVE builds with staples since the day I tried them. The framed staple was my favourite. But I had to dryburn it every two days because the wrap gunked up and when I fired them without topcap and saw the vape flowing out at very few areas where there was little gunk.

When I tried the staple helix that has less surface area I was stunned how much better the vape was and it lasts for days if not a week without loosing flavour.

I guess this build offers so much holes beneath the twisted wire and the ribbon for the juice to wick in and the vape to exhaust out what explains the advantage.

So in conclusion there are way more factors like ramp up, temperature, wicking and durability of the coil and for sure many more factors that influence flavour.

Sent from my SM-G920V using Tapatalk

I did an experiment a while back and did 2 sets of fused claptons. Sorry no pics but they were both 2x28gNi80 one i wrapped in 38g the other i did in 44g. The 44g set were not at all inpressive. I think because the fine wraps were so tight that they nearly sealed off the cores. Anyone else observe this?

Sent from my SM-G920V using Tapatalk

Sent from my SM-G920V using Tapatalk

Looks tight to me!Well this is nothing special to what you guys are making but here's my first coil. Any criticism or feedback would be great.

View attachment 78094

Sent from my SM-G920V using Tapatalk

The video is well worth watching IMO.Nice micro Clapton zippers, very clean and colored beautiful !

So in some cases you are right, more surface is sometimes more flavorful but not in any cases.

Every coil build has its own properties, and I was hunting for more and more surface area. But in my opinion (!!) some builds with very large surface area will loose their advantage very fast, when they gunk up and the tiny wraps will totally disappear because they are lost in juice caramelization.

So why do people say aliens have better flavour as fused claptons but the only difference is the wrap? Well I think it's the wicking properties and the wrap leaves way more space for the vape to exhaust.

I will give you an example. I LOVE builds with staples since the day I tried them. The framed staple was my favourite. But I had to dryburn it every two days because the wrap gunked up and when I fired them without topcap and saw the vape flowing out at very few areas where there was little gunk.

When I tried the staple helix that has less surface area I was stunned how much better the vape was and it lasts for days if not a week without loosing flavour.

I guess this build offers so much holes beneath the twisted wire and the ribbon for the juice to wick in and the vape to exhaust out what explains the advantage.

So in conclusion there are way more factors like ramp up, temperature, wicking and durability of the coil and for sure many more factors that influence flavour.

Thanks his videos are very good. Ill give it a try this weekend doesnt look too tough.The video is well worth watching IMO.

Sent from my SM-G920V using Tapatalk

Here's some eye candy of the single coil i dropped in the Merlin Mini RTA.

•8x.3mm/42g/4x.3mm/42g

•kanthal ribbon/n80 outer

•4 wrap @ 3mm clocked in at .15 ohms.

•i made an awesome video of the performance but i guess we can no longer upload video? I asked about it the other day but received no answer. So for now y'all are stuck with a bunch of photos haha

I love everything about this tank. And i'm always surprised by the builds it can handle. If anyone knows anything about uploading video lemme know, i'm curious what happened. Cheers!

IG: @helix.arcanum

Sent from my iPhone using Tapatalk

•8x.3mm/42g/4x.3mm/42g

•kanthal ribbon/n80 outer

•4 wrap @ 3mm clocked in at .15 ohms.

•i made an awesome video of the performance but i guess we can no longer upload video? I asked about it the other day but received no answer. So for now y'all are stuck with a bunch of photos haha

I love everything about this tank. And i'm always surprised by the builds it can handle. If anyone knows anything about uploading video lemme know, i'm curious what happened. Cheers!

IG: @helix.arcanum

Sent from my iPhone using Tapatalk

Looks good!Well this is nothing special to what you guys are making but here's my first coil. Any criticism or feedback would be great.

View attachment 78094

TrackDay

VU Donator

Silver Contributor

Member For 3 Years

Member For 2 Years

Member For 1 Year

ECF Refugee

Looks good!Congrats on your first coil. Are you planning on doing more builds in the future, or was this a one-time thing?

Thanks man, I'll definitely be doing more builds. I'm waiting for my coil master coiling jigs to finally get here. I've still got one that came with original coil master kit but it never hurts to stock up

Twisted coils were the second kind of coil that I learned how to do. They aren't too difficult to make and they vape great. Fused Claptons were the third kind of coil I ever made and, while more difficult than a twisted coil to make, aren't too difficult, either. I, myself, am still perfecting my Fused Clapton so that there are almost no gaps.Thanks man, I'll definitely be doing more builds. I'm waiting for my coil master coiling jigs to finally get here. I've still got one that came with original coil master kit but it never hurts to stock up. Next on the cook book will be twisted and fused claptons.

Good luck with your future builds!

Test•i made an awesome video of the performance but i guess we can no longer upload video?

Test

Thanks, it must be this damn Tapatalk app then. It wont even show my "videos" folder on my phone. I appreciate it!

Sent from my iPhone using Tapatalk

And todays build

Still testing corrugated coils. Atempted a quite Nice pair of corrugated Staple Staggered Fused Clapton.

Wire Used: 4ply 0.3 Ribbon straight, 2 ply 0.3 corrugated.

30GA for the frames, 36GA for the stagger and 42GA Fuse. As usual, all N80.

5 wraps 3mm @ 0.135 Ohm Dual sitting on my Big Bear RDTA from EHPro.

The only Part i Messed up a litte was the fuse, but the rest is Perfect. Had to use about 7 Inches of ribbon for ribbon sliders to Hold everything in Place! This ist because 0.3 N80 Ribbon is so Hard to handle especially when corrugated, when i Used some 0.5 Kanthal some Time ago for a SSFC the whole prep work was done in 5 minutes(stapling).

For todays Build the prep lasts me half an Hour with a lot of Hot glue and tape anyways the result is stunning. These coils are so airy with stunning wicking properties and Zero to None rampup. Warmth and Flavour are Amazing. And a VERY thick and dense Vape.

anyways the result is stunning. These coils are so airy with stunning wicking properties and Zero to None rampup. Warmth and Flavour are Amazing. And a VERY thick and dense Vape.

And Last but not least the honored Last two Inches at the swivel End.

Still testing corrugated coils. Atempted a quite Nice pair of corrugated Staple Staggered Fused Clapton.

Wire Used: 4ply 0.3 Ribbon straight, 2 ply 0.3 corrugated.

30GA for the frames, 36GA for the stagger and 42GA Fuse. As usual, all N80.

5 wraps 3mm @ 0.135 Ohm Dual sitting on my Big Bear RDTA from EHPro.

The only Part i Messed up a litte was the fuse, but the rest is Perfect. Had to use about 7 Inches of ribbon for ribbon sliders to Hold everything in Place! This ist because 0.3 N80 Ribbon is so Hard to handle especially when corrugated, when i Used some 0.5 Kanthal some Time ago for a SSFC the whole prep work was done in 5 minutes(stapling).

For todays Build the prep lasts me half an Hour with a lot of Hot glue and tape

And Last but not least the honored Last two Inches at the swivel End.

Thanks for the motovation! Heres my 1st staple helix 28gNi80/6ply.4/36g&40gNi80 wrap. Turned out ok. Building the wire went good but realized i didnt get it quite tight enough because coiling it was challenging. The ribbon twisted to an angle between the frames.The video is well worth watching IMO.

Sent from my SM-G920V using Tapatalk

Flavor it amazing!Thanks for the motovation! Heres my 1st staple helix 28gNi80/6ply.4/36g&40gNi80 wrap. Turned out ok. Building the wire went good but realized i didnt get it quite tight enough because coiling it was challenging. The ribbon twisted to an angle between the frames.

Sent from my SM-G920V using Tapatalk

Sent from my SM-G920V using Tapatalk

Did this Staple Helix last weekend.. had 3 strands of Twisted ribbon wire laying around and I ran 2 more plys of ribbon wire on each side. The pre-wrapped wire looked really good but when I wrapped it.. the twisted ribbon wire kinda stretched a bit and it lost some of its twists. Vapes like a Champ though!

Congrats!! Looks awesome ManThanks for the motovation! Heres my 1st staple helix 28gNi80/6ply.4/36g&40gNi80 wrap. Turned out ok. Building the wire went good but realized i didnt get it quite tight enough because coiling it was challenging. The ribbon twisted to an angle between the frames.

Sent from my SM-G920V using Tapatalk

Yeah coiling is the real Challenge with these coils Since the wrap of helixed staples is pretty loose compared to a Full or staggered fuse.

Totally messed up my First corrugated Helix build.

It helps a bit when you take Nylon pliers or toothless pliers wrapped with some soft tape and gently press the whole Length of the finished wire to get everything in place.

Thats the reason why i dont use the fancy Helix wrap with angled stripes, because at least me can't coil them up.

Thanks for the motovation! Heres my 1st staple helix 28gNi80/6ply.4/36g&40gNi80 wrap. Turned out ok. Building the wire went good but realized i didnt get it quite tight enough because coiling it was challenging. The ribbon twisted to an angle between the frames.

Sent from my SM-G920V using Tapatalk

Did your Ribbon Wire end up laying horizontally instead of vertically when coiling it?

It stayed vertical when i built the stick. Just rolled mabey 20degrees from vertical when i coiled it on a 3.5mm bit. You can see if you zoom in. Sorry i really need a macro lens.Did your Ribbon Wire end up laying horizontally instead of vertically when coiling it?

Sent from my SM-G920V using Tapatalk

Thanks! I nylon plyers are definitely the list.Congrats!! Looks awesome Man

Yeah coiling is the real Challenge with these coils Since the wrap of helixed staples is pretty loose compared to a Full or staggered fuse.

Totally messed up my First corrugated Helix build.

It helps a bit when you take Nylon pliers or toothless pliers wrapped with some soft tape and gently press the whole Length of the finished wire to get everything in place.

Thats the reason why i dont use the fancy Helix wrap with angled stripes, because at least me can't coil them up.

Sent from my SM-G920V using Tapatalk

KingPin!

In my defence, I was left unsupervised ^^

VU Donator

Platinum Contributor

Member For 4 Years

VU Challenge Team

Reviewer

After my disasterous first attempt at a framed staple I had another go today well pleased with it

I had that you fucking muppet kingpin moment when I went to mount them and noticed I twisted the top coil the wrong poxy way lmao so I had to unwind it and wind it back again ...this time the right way but they were perfectly aligned first time you'll have to believe me (the air was blue)

Still compared to an alien this coil it well worth the effort completely blows it away flavour is outstanding I'm well impressed ...managed to fit these in the boreas deck ....just!

Used

6 x 0.4 x 0.1KA1 ribbon

2x 28g KA1 Frames

38g NI80 wrap

7wraps with a 3mm diameter came out at 0.16ohms

I had that you fucking muppet kingpin moment when I went to mount them and noticed I twisted the top coil the wrong poxy way lmao so I had to unwind it and wind it back again ...this time the right way but they were perfectly aligned first time you'll have to believe me (the air was blue)

Still compared to an alien this coil it well worth the effort completely blows it away flavour is outstanding I'm well impressed ...managed to fit these in the boreas deck ....just!

Used

6 x 0.4 x 0.1KA1 ribbon

2x 28g KA1 Frames

38g NI80 wrap

7wraps with a 3mm diameter came out at 0.16ohms

I cant believe you were able to unwind and recoil that one!!! Nice work. My 1st set took forever too but it was worth it. Theyre still perfect after 7 weeks and 8 or 9 cleanings!After my disasterous first attempt at a framed staple I had another go today well pleased with it

I had that you fucking muppet kingpin moment when I went to mount them and noticed I twisted the top coil the wrong poxy way lmao so I had to unwind it and wind it back again ...this time the right way but they were perfectly aligned first time you'll have to believe me (the air was blue)

Still compared to an alien this coil it well worth the effort completely blows it away flavour is outstanding I'm well impressed ...managed to fit these in the boreas deck ....just!

Used

6 x 0.4 x 0.1KA1 ribbon

2x 28g KA1 Frames

38g NI80 wrap

7wraps with a 3mm diameter came out at 0.16ohms

View attachment 78200

View attachment 78201

View attachment 78202

View attachment 78203

Sent from my SM-G920V using Tapatalk

KingPin!

In my defence, I was left unsupervised ^^

VU Donator

Platinum Contributor

Member For 4 Years

VU Challenge Team

Reviewer

KingPin!

In my defence, I was left unsupervised ^^

VU Donator

Platinum Contributor

Member For 4 Years

VU Challenge Team

Reviewer

I cant believe you were able to unwind and recoil that one!!! Nice work. My 1st set took forever too but it was worth it. Theyre still perfect after 7 weeks and 8 or 9 cleanings!Now that i have a few sets under my belt it takes 45min. Not fast yet but for as long as they last its worth the time. Enjoy!

Sent from my SM-G920V using Tapatalk

Nice! hope these last a few cycles as well ....I can't believe it either took me the best part of 4 hours to make those lol I was so pissed off was considering running a single coil for a bit but some hard tugging on the re wind helped!

These are going to be my go to coil build from now on I think

Framed Staples are Awesome and worth the time spent making!

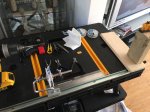

Haha awesome work and lot of endurance man! Really like the result and your work desk is pretty neat cool idea with the spool sliderAfter my disasterous first attempt at a framed staple I had another go today well pleased with it I had that you fucking muppet kingpin moment when I went to mount them and noticed I twisted the top coil the wrong poxy way lmao so I had to unwind it and wind it back again ...this time the right way but they were perfectly aligned first time you'll have to believe me (the air was blue) Still compared to an alien this coil it well worth the effort completely blows it away flavour is outstanding I'm well impressed ...managed to fit these in the boreas deck ....just!

Staple coils are definitely worth the effort and you will get more and more practice. My first framed staples took me about 2 hours now I can two a set from beginning to the end within 15 minutes or less. I know exactly what and how to do when and where mistakes can happen.

But I can hardly recommend to try helixed staples, for some reasons for me they are easier to build and are a big step forward in performance and flavour (just my opinion) and the corrugated ones are definitely a big step forward but they are a BITCH to make and to coil since especially 0.3 ribbon is so unforgiving and fragile and loves to get out of stack. But as usual, a matter of practice and patience.

At this point, my best performing coils so far are the corrugated staple staggered fused and after all they where not that hard to build. I can run them at 80 watts where i would have to run normal framed staples at 110 watts to get the same result, but I like the flavour of the corrugated SSFC more.

Sadly staple builds are quite unforgiving when it comes to coiling. But I HARDLY recommend to use 0.3 ribbon for corrugating or helix builds because they are much easier to coil and won't loose their shape so easily.

Just keep your patience and congrats for this big step

Last edited:

KingPin!

In my defence, I was left unsupervised ^^

VU Donator

Platinum Contributor

Member For 4 Years

VU Challenge Team

Reviewer

Haha awesome work and lot of endurance man! Really like the result and your work desk is pretty neat cool idea with the spool slider

Staple coils are definitely worth the effort and you will get more and more practice. My first framed staples took me about 2 hours now I can two a set from beginning to the end within 15 minutes or less. I know exactly what and how to do when and where mistakes can happen.

But I can hardly recommend to try helixed staples, for some reasons for me they are easier to build and are a big step forward in performance and flavour (just my opinion) and the corrugated ones are definitely a big step forward but they are a BITCH to make and to coil since especially 0.3 ribbon is so unforgiving and fragile and loves to get out of stack. But as usual, a matter of practice and patience.

At this point, my best performing coils so far are the corrugated staple staggered fused and after all they where not that hard to build. I can run them at 80 watts where i would have to run normal framed staples at 110 watts to get the same result, but I like the flavour of the corrugated SSFC more.

Sadly staple builds are quite unforgiving when it comes to coiling. But I HARDLY recommend to use 0.3 ribbon for corrugating or helix builds because they are much easier to coil and won't loose their shape so easily.

Just keep your patience and congrats for this big step

Thanks matey means a lot hehe now I know I can do these I will be trying some more exoctic staples who knows maybe I can crack out a staggerton or something like those helixes you mentioned I'll be well stocked ...I was buzzing earlier lol so good when you get a good build that accomplishment feeling... was saying to my wife check this out isn't it great ...."erm yeah it's great" is this what all the swearing was about, looks like a coil to me....a coil?! Look this is bloody difficult, just a coil pfffffffff

Gonna try a tiger coil except twist some claptons then go round with ribbon see what that is like

Also must get a pair of aliens at least once so far managed to make just one coil that was really decent before I do that though gonna order some 36 gauge wire as I have none at the moment everything I do is 38g wrap

...is there a way to space on a framed staple without wrapping with parallel wrap and unwrapping one of them? I assume you can't use the button trick because of its shape?

the standard loop trick works. just do the button trick, but instead of a button tied tight to the cores, you tie an atomizer to a slightly longer wire so it hangs between your cores and table somewhere. you can also hold that loop with a spare finger instead of wieghing it down, if you have giant hands. ill try to get a picture later if you want, i was planning to try a regular staggerton today instead of groove fusedis there a way to space on a framed staple without wrapping with parallel wrap and unwrapping one of them? I assume you can't use the button trick because of its shape?

KingPin!

In my defence, I was left unsupervised ^^

VU Donator

Platinum Contributor

Member For 4 Years

VU Challenge Team

Reviewer

the standard loop trick works. just do the button trick, but instead of a button tied tight to the cores, you tie an atomizer to a slightly longer wire so it hangs between your cores and table somewhere. you can also hold that loop with a spare finger instead of wieghing it down, if you have giant hands. ill try to get a picture later if you want, i was planning to try a regular staggerton today instead of groove fused

Thanks machine I'll try this next...

Talk me through a groove fused what's the steps in it exactly? There are so many coil names now can't keep up with them all lol need some sort of picture list like a sticker book we can tick off as we go ...there you go someone that's a thread all on its own hehe

groove fused is when you fuse something together like a ssfc, but you dont space the first pass using a loop trick or parallel claptons. your fuse just sits on top of the first pass of wraps, in the grooves. the key is to use something thicker for the first pass and something very thin for the second pass, so the grooves will be deep enough, and the fuse small enough that they all fit together.

What did this groove ohm out at?@whiteowl84

What is this called? And what does it consist of?

View attachment 76718

I can't stop looking at it.

Sent from my SM-G920V using Tapatalk

Thats cool. Does it slide easy enough to follow a 40g+clapton without having to push it along?Oh yeah you know a few pages back I was talking about using that drill bit to hold the wire centre and fishing spool holder to hold the wrap spool using some sort of slider ...here is my work bench with it all set up makes life so much easier

View attachment 78205

Sent from my SM-G920V using Tapatalk

A simple explanation would be like this: if you made two regular 28/38g clapton wires and fused them together with 42g, so that the 42g sits in the grooves in the 38g and holds the two wires together. I'll dig through my Google Drive and see if I can find a shot of em for yaThanks machine I'll try this next...

Talk me through a groove fused what's the steps in it exactly? There are so many coil names now can't keep up with them all lol need some sort of picture list like a sticker book we can tick off as we go ...there you go someone that's a thread all on its own hehe

Sent from my C6740N using Tapatalk

KingPin!

In my defence, I was left unsupervised ^^

VU Donator

Platinum Contributor

Member For 4 Years

VU Challenge Team

Reviewer

For those who don't follow me on instagram.

26/36n80 aliens parallel with 26/36n80 claptons.

10x .5k ribbon, 28n80 frames, 38/40n80 Staggertons in the new Druga rda by Augvape.

Very nice Dutch! Great work how you liking the druga? Noticed few posts back Raymo said the post screws were not great

Thanks mate @KingPin!, I honestly didn't vape it yet, the + on the screws could be engraved a little deeper imo.Very nice Dutch! Great work how you liking the druga? Noticed few posts back Raymo said the post screws were not great

Besides that i haven't had any issues with it yet, but i've just putten one build in there so time wil tell

I have no idea. That was months ago. It was only 6 ply with 28g frames and a 30/32g Clapton.What did this groove ohm out at?

Sent from my SM-G920V using Tapatalk

Over 0.1