It took me a while to get them down well enough.

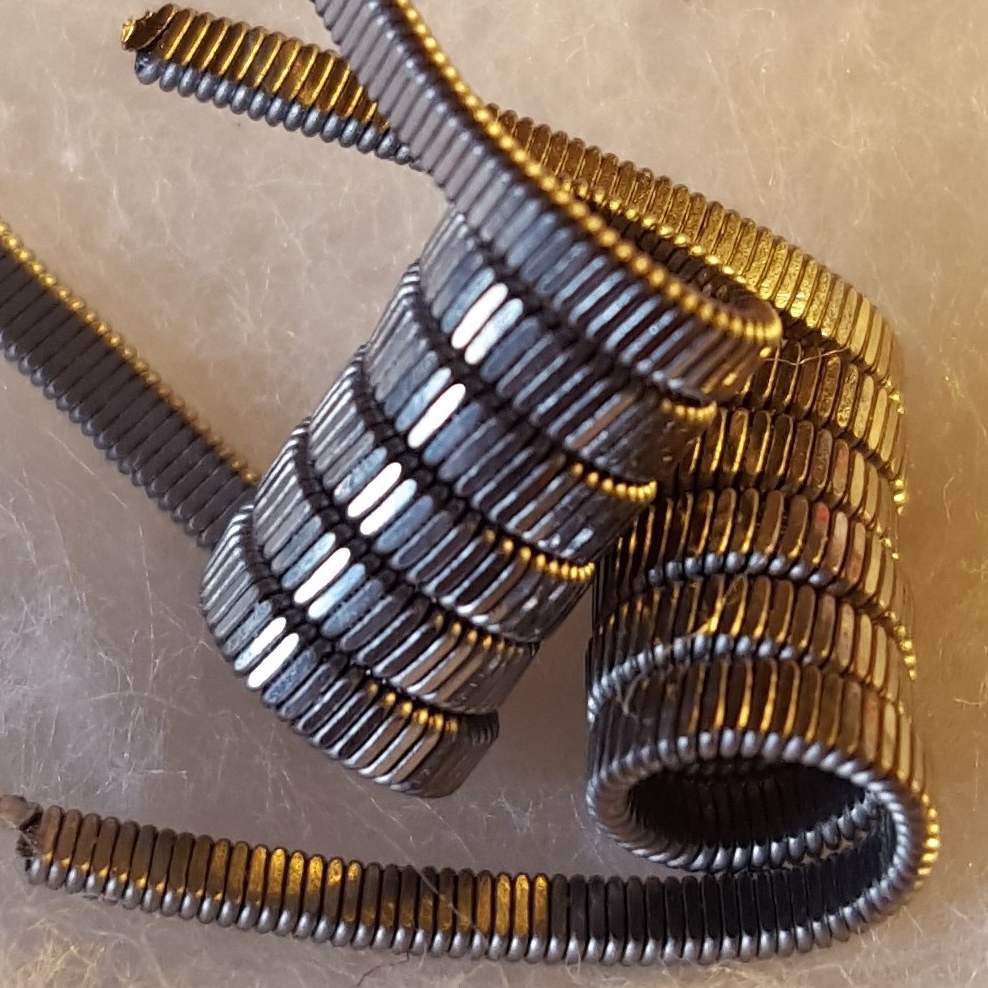

The few things I suggest is getting key rings, you twist them on the cores as a slider or utilize flat wire the same and pinch... I use 3- 3/4” diameter key rings across a 12” run

Next is having the drill anchored also, this allows you to pull the tension tight rather than relying on holding a drill stationary, I use speed clamps like this

And lay the drill on its side and clamp it to my desk... others use a vise... these are lighter and do the same thing. And since your build station allows you to adjust your swivel height, this might be something to aid in getting tighter tension.

Next I don’t do the whole 12” run let’s say left to right, I start left and go to the middle, then reverse the drill and right to left, this I’ve found eliminates additional twisting of the cores.

Lastly is the stretch, probably the most pivotal point. I suggest understretching the Decore... start trying to wrap, if you need to put tension for it to wrap, stretch just a tad more, then spin a few wraps worth... you should barely have to hold a lead on wrapping for it to just wrap itself...

Then it’s all about speed, I can’t wrap aliens fast like some, I have the drill on low speed which is like a max of 250 rpm, and I half squeeze the trigger to go slower.

I’m no magician, I still mess up making them... plus it only takes 8” of total wire to make a pair of 3mm 5 wraps

Oh yeah, I don’t place the cores within the jaws of the drill clutch, I cut the length down on a Bobby pin, can use a simple eye hole threaded bolt also, but wife had Bobby pins so I stole a few

Sent from my iPhone using Tapatalk