Looks like a great build brother! Awesome job!Same 3*16/36 aliens from last week but now spaced more and in the wormhole rda. Sitting @.16 ohms @80W with some homemade 3mg French vanilla. It's a tasty cloud in the wormhole.

View attachment 131315

I know the pic sucks but it's the best I could do.

Forgot to take pics but I was able to flatten out the framed staple build enough to deem it useable. It's a warmer vape than the aliens but also more tasty.

Become a Patron!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Post your builds

- Thread starter Vape_geek

- Start date

OriginallyI wasn't going to vape it as a single coil, but got this awesome Engine Nano and though that would make one insane vape. I was definitely disappointed. Flavor for days and for a single coil it is really cloudy too. This is a seriously good vape bro.Bro I’m so sorry I didn’t realize you were gonna use it as a single I would have made the resistance a lot lower. I hope it still vapes well. If it’s regulated it shouldn’t really make too much of a difference but that’s my bad. If you want a lower resistance Fralien just let me know!

Sent from my LGMP450 using Tapatalk

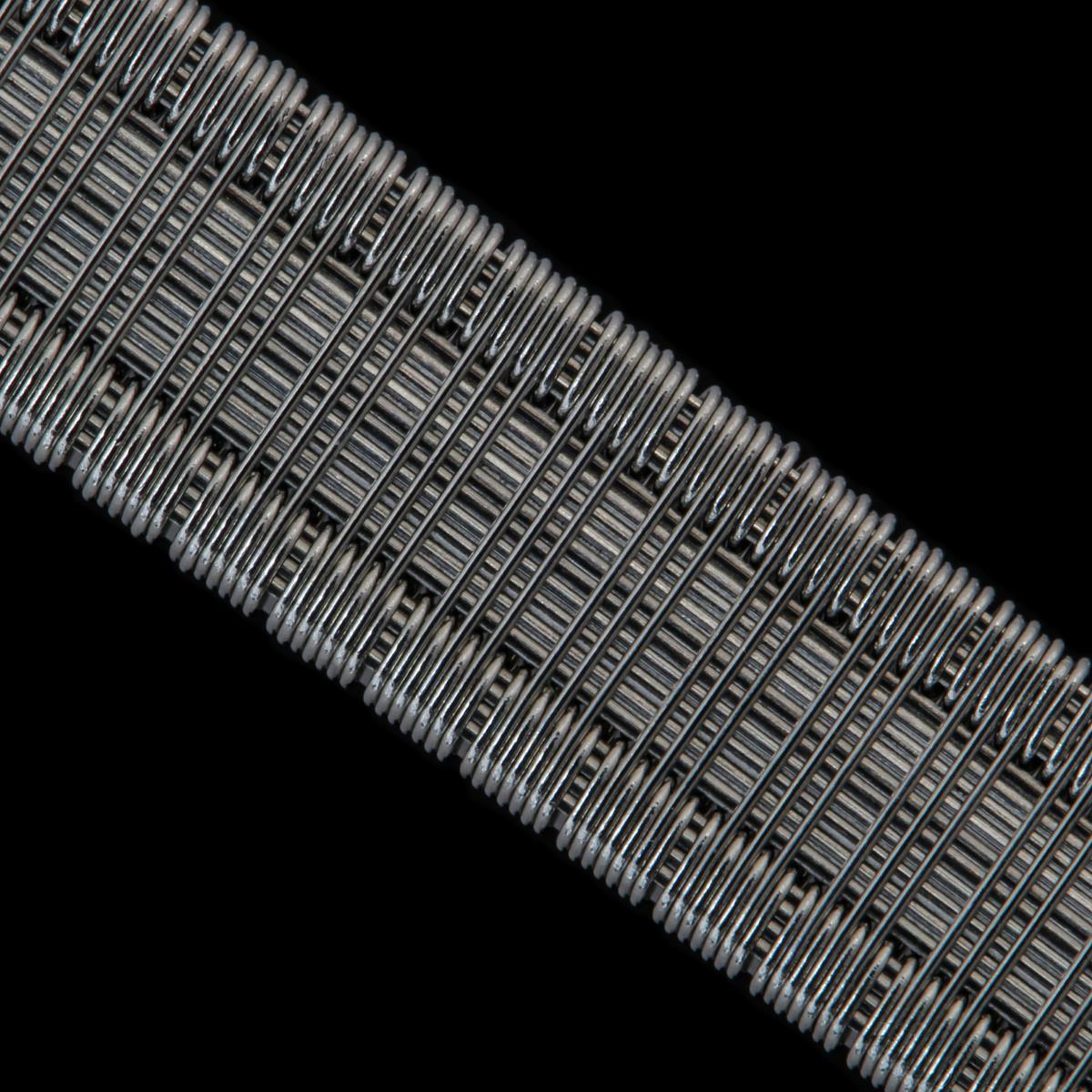

This is really great I like how you skip fused in the last photo and added an angle on the second pass that’s something I’d like to try. Very awesome.Some SSFC Wire Shots

18ply .3R/42g

What disappoints you about it? Is there anything I can build to remedy it for you? You were the first person that responded to my thread so whatever you want you got it. I can make a single coil that will blow J-lo’s tits off. Just let me know!OriginallyI wasn't going to vape it as a single coil, but got this awesome Engine Nano and though that would make one insane vape. I was definitely disappointed. Flavor for days and for a single coil it is really cloudy too. This is a seriously good vape bro.

Sent from my LGMP450 using Tapatalk

Stupid Auto spell, not what I was saying LOL. I was trying to say seriously NOT disappointed LOL. Sorry, I missed that booboo. No man,it is an elite build and vapes like a beast.What disappoints you about it? Is there anything I can build to remedy it for you? You were the first person that responded to my thread so whatever you want you got it. I can make a single coil that will blow J-lo’s tits off. Just let me know!

Sent from my LGMP450 using Tapatalk

Jlo dosnt have tits...now say your build will knock her ass off and ill be impressedWhat disappoints you about it? Is there anything I can build to remedy it for you? You were the first person that responded to my thread so whatever you want you got it. I can make a single coil that will blow J-lo’s tits off. Just let me know!

Sent from my SM-G950U using Tapatalk

Man it d got quiet in here all of a sudden.

Sent from my LGMP450 using Tapatalk

Sent from my LGMP450 using Tapatalk

I’m just happy you weren’t disappointed in any way.Man it d got quiet in here all of a sudden.

Sent from my LGMP450 using Tapatalk

That's a seriously clean build though. Perfection

Sent from my LGMP450 using Tapatalk

When I look at this pic, why do I feel like Homer drooling over a donut? I need a bib!

I know right? That alien is gorgeousWhen I look at this pic, why do I feel like Homer drooling over a donut? I need a bib!

Sent from my LGMP450 using Tapatalk

When I look at this pic, why do I feel like Homer drooling over a donut? I need a bib!

Thanks guys! It's actually not completely perfect there is one wrap that is ever so slightly off but it's so minimal you wouldn't even be able to see it without a macro shot, so it's not gonna affect the vape for whoever receives it. It's an Alien Framed Staple (Fralien) with 28g frames, .4 4ply ribbon and a 38g alien wrap. Really nice of you guys to say though. I consider both of you guys allies and friends in the building world and mark my words before you know it you will be doing similar builds and people will know both of you as really good builders. It's been a long time but I swear it only seems like yesterday that I was figuring out how to do a staple coil. Time flies by so fast and you get better and better everyday. One of the only few things I like as much as building is rooting for other builders that are just starting out and seeing their progress. That's as exciting to me as seeing my own progress. I've been meaning to make some tutorials cause I think I can explain some information that may or may not help builder who are starting out get that Alien or Fralien a little more frequently; just some things I think of that aren't pointed out in the tutorials I've seen to this point. I would however say the best tutorials right now come from NDevine83... I think that's his name. He has his own Youtube channel. I'm debating starting my own channel to try to help some people that are starting off, but it's not like I'm some influencer that is doing anything that is revolutionary in the big picture there are plenty of better builders than me. I just think it would be cool to help some people cause I know how hard starting off is.I know right? That alien is gorgeous

Sent from my LGMP450 using Tapatalk

Thank you, I still have a long way before I can consider myself even a novice yet, but I'm get there.Thanks guys! It's actually not completely perfect there is one wrap that is ever so slightly off but it's so minimal you wouldn't even be able to see it without a macro shot, so it's not gonna affect the vape for whoever receives it. It's an Alien Framed Staple (Fralien) with 28g frames, .4 4ply ribbon and a 38g alien wrap. Really nice of you guys to say though. I consider both of you guys allies and friends in the building world and mark my words before you know it you will be doing similar builds and people will know both of you as really good builders. It's been a long time but I swear it only seems like yesterday that I was figuring out how to do a staple coil. Time flies by so fast and you get better and better everyday. One of the only few things I like as much as building is rooting for other builders that are just starting out and seeing their progress. That's as exciting to me as seeing my own progress. I've been meaning to make some tutorials cause I think I can explain some information that may or may not help builder who are starting out get that Alien or Fralien a little more frequently; just some things I think of that aren't pointed out in the tutorials I've seen to this point. I would however say the best tutorials right now come from NDevine83... I think that's his name. He has his own Youtube channel. I'm debating starting my own channel to try to help some people that are starting off, but it's not like I'm some influencer that is doing anything that is revolutionary in the big picture there are plenty of better builders than me. I just think it would be cool to help some people cause I know how hard starting off is.

I think it would be great for you to do a channel. I do watch n.devine83 as well as twisted messes, Sherlock Holms is another good one and Mind Forge. Every builder dies things differently and some aren't as thorough as others in their explanations. I think you'd do well in this capacity. Just make sure you let me know when you do so that I can subscribe to your channel.

Sent from my LGMP450 using Tapatalk

and this is why we and many others like you so much Shred, you are one humble dude and with mad fucking skills!Thanks guys! It's actually not completely perfect there is one wrap that is ever so slightly off but it's so minimal you wouldn't even be able to see it without a macro shot, so it's not gonna affect the vape for whoever receives it. It's an Alien Framed Staple (Fralien) with 28g frames, .4 4ply ribbon and a 38g alien wrap. Really nice of you guys to say though. I consider both of you guys allies and friends in the building world and mark my words before you know it you will be doing similar builds and people will know both of you as really good builders. It's been a long time but I swear it only seems like yesterday that I was figuring out how to do a staple coil. Time flies by so fast and you get better and better everyday. One of the only few things I like as much as building is rooting for other builders that are just starting out and seeing their progress. That's as exciting to me as seeing my own progress. I've been meaning to make some tutorials cause I think I can explain some information that may or may not help builder who are starting out get that Alien or Fralien a little more frequently; just some things I think of that aren't pointed out in the tutorials I've seen to this point. I would however say the best tutorials right now come from NDevine83... I think that's his name. He has his own Youtube channel. I'm debating starting my own channel to try to help some people that are starting off, but it's not like I'm some influencer that is doing anything that is revolutionary in the big picture there are plenty of better builders than me. I just think it would be cool to help some people cause I know how hard starting off is.

agree with you on N.Devine as well. I enjoy his videos a lot and he's the YouTube builder I watch most.

I wanna see her wickedView attachment 131408 View attachment 131409 View attachment 131410 Made this wire just to goof around with a friend. I wanted to know if I could put it into a atty without screwing the spaces so much... pita I would say, lol

Sent from my SM-G950U using Tapatalk

KingPin!

In my defence, I was left unsupervised ^^

VU Donator

Platinum Contributor

Member For 4 Years

VU Challenge Team

Reviewer

Don’t know what you mean looks spot on to me mate

That’s a really nice looking wire, why not just coil it up like you normally would, was the huge spacing intentionally done? It’s a very cool looking build. You’ve been on fire lately!View attachment 131408 View attachment 131409 View attachment 131410 Made this wire just to goof around with a friend. I wanted to know if I could put it into a atty without screwing the spaces so much... pita I would say, lol

Thanks bro. But that wire was not supposed to be vapedThat’s a really nice looking wire, why not just coil it up like you normally would, was the huge spacing intentionally done? It’s a very cool looking build. You’ve been on fire lately!

Best.

You said it brotherOut of all the simple fundamental builds the SSFC have to be my favorite one to make. I also think it’s a coil that vapes great. I really enjoy making these.

View attachment 131434

Ok man, seriously, what in the fuuuuuuuck?!?!Conspiracy RDA with a Triple Threat Build

SSFC Variant: 18ply .3R/40N90

Aliens are 3x27N90/38N90

Wow. Hey man, from one fucker to another, well done! That is just absolutely bonkers! In the best way of course! I have a raging vape stiffy!!!

DAMN! That's just beautiful. One day man, one dayConspiracy RDA with a Triple Threat Build

SSFC Variant: 18ply .3R/40N90

Aliens are 3x27N90/38N90

Sent from my LGMP450 using Tapatalk

One of the things I love about your work is your style. Simple, clean, elegant!! I can spot a raymo coil/set-up/shot a mile away. I also love the fact that you almost always do a true 1/3 alien. Most people move on to bigger swooshes as they skill-up. And while they do add some cool affects ... I still think this ratio looks best on a 3 core.Conspiracy RDA with a Triple Threat Build

SSFC Variant: 18ply .3R/40N90

Aliens are 3x27N90/38N90

Good stuff man

I agree with the 3:1 ratio looking and functioning the best. I'm not saying that giant swooshes aren't fun but practically I think if you stay as close to the math as possible your gonna get the best performing coil. There's also the stretch and the tension that factor into it but I would almost always go with 3:1 if I could. Sometimes I gotta find little accommodation ranges but regular 3:1 alien claptons still vape great.One of the things I love about your work is your style. Simple, clean, elegant!! I can spot a raymo coil/set-up/shot a mile away. I also love the fact that you almost always do a true 1/3 alien. Most people move on to bigger swooshes as they skill-up. And while they do add some cool affects ... I still think this ratio looks best on a 3 core.

Good stuff man

Last edited:

@raymo2u,Conspiracy RDA with a Triple Threat Build

SSFC Variant: 18ply .3R/40N90

Aliens are 3x27N90/38N90

You never stop impressing me! As soon as I think I've seen all (and the best) of your work you come along with something tasteful and beautiful! I have to agree with other's comments here when, as we say down south; your work stands out like a turd in a punch bowl! But it's like a polished, color shot Nichrome/SS316L turd in a very dingy yucky punch bowl...

http://vapingunderground.com/threads/wts-wtt-aspex-performance-coils.434798/

Awesome aliens and so clean!Dual 5 cores

View attachment 131672

Thanks brother. These are 5 core aliens. 28g cores, 24g decore, 36g binding. BTW I got the Kanthal you shipped to me. Thank you!! Now I can build you whatever you want.. so think about what you'd really love to vape and I'll make it happen!!Awesome aliens and so clean!

Awesome dude, that was quick! Thank you brother!!!Thanks brother. These are 5 core aliens. 28g cores, 24g decore, 36g binding. BTW I got the Kanthal you shipped to me. Thank you!! Now I can build you whatever you want.. so think about what you'd really love to vape and I'll make it happen!!

I'll shoot you a pm.

I swear, I love coming to this thread and and drooling over the mastery of the true artists here. That's ok, it looks like I'll have vape mail tomorrow after I get off work, which means I'll be building. Thinking I'm finally going to try that zipper coil. It looks like a beast. I'm really looking forward to it.

Sent from my LGMP450 using Tapatalk

Sent from my LGMP450 using Tapatalk

idk how long you've been building so please don't be insulted ... this is all purely to try and be helpful ...I swear, I love coming to this thread and and drooling over the mastery of the true artists here. That's ok, it looks like I'll have vape mail tomorrow after I get off work, which means I'll be building. Thinking I'm finally going to try that zipper coil. It looks like a beast. I'm really looking forward to it.

Sent from my LGMP450 using Tapatalk

The most difficult thing about zippers is getting 2 strand of twisted wire the have an even twist. Unless you twist from both sides, which is obviously difficult, the wires do not twist evenly from end to end. They will always start twisting from the chuck end (or the end that is doing the spinning). So that end will always be a bit tighter of a twist. The remedy for this is to twist until you have the pitch, on the chuck end, just a little wider than you want to end up with. Then flip the stick and twist the other end until it has the same pitch. This is obviously a ridiculous notion considering that a tenth of a mm difference is noticeable when it sets everything off just enough so that the humps don't line up across the coil. The quick fix for this is to twist one side until it breaks and then flip and twist the other till it breaks. But this leads to other problems. If the tension between the 2 wires isn't damn near perfect then your stick will break somewhere in the middle where the slack is, instead of at the chuck end. It also means your stuck with a super tight twist whether you like it or not. Not only does this limit the look of your build to a single outcome, it also affect how the coil functions. Super tight twists tend to be fraught with hot spots. Then comes the wrapping ... Twisted wire is springy as hell. It's already a PITA to get a twisted wire coiled nice and neat. Then you add another one and your trying to keep them lined up to get that zipper affect. Lots of pulling and adjusting and tightening ...

I know that looks like a lot of build up to a hard build. But, in the end it is not difficult. Once, you have a feel for how wire will act in most situations you'll develop intuitions that make all this stuff trivial even if you've never attempted the build before.

Good luck and let us know how it turns out

CrazyChef v2.0

Platinum Contributor

ECF Refugee

VU Challenge Team

Member For 5 Years

Reddit Exile

VU Patreon

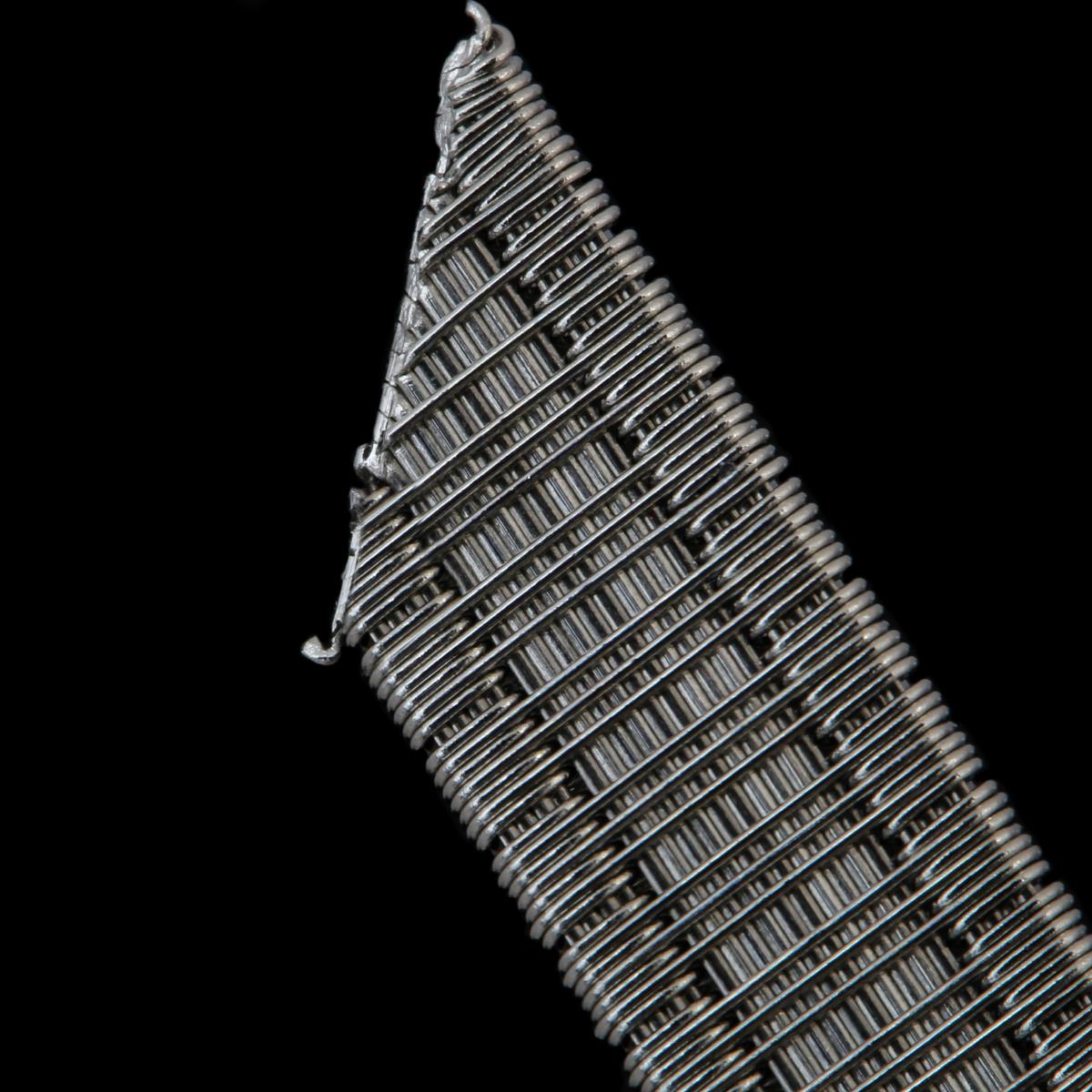

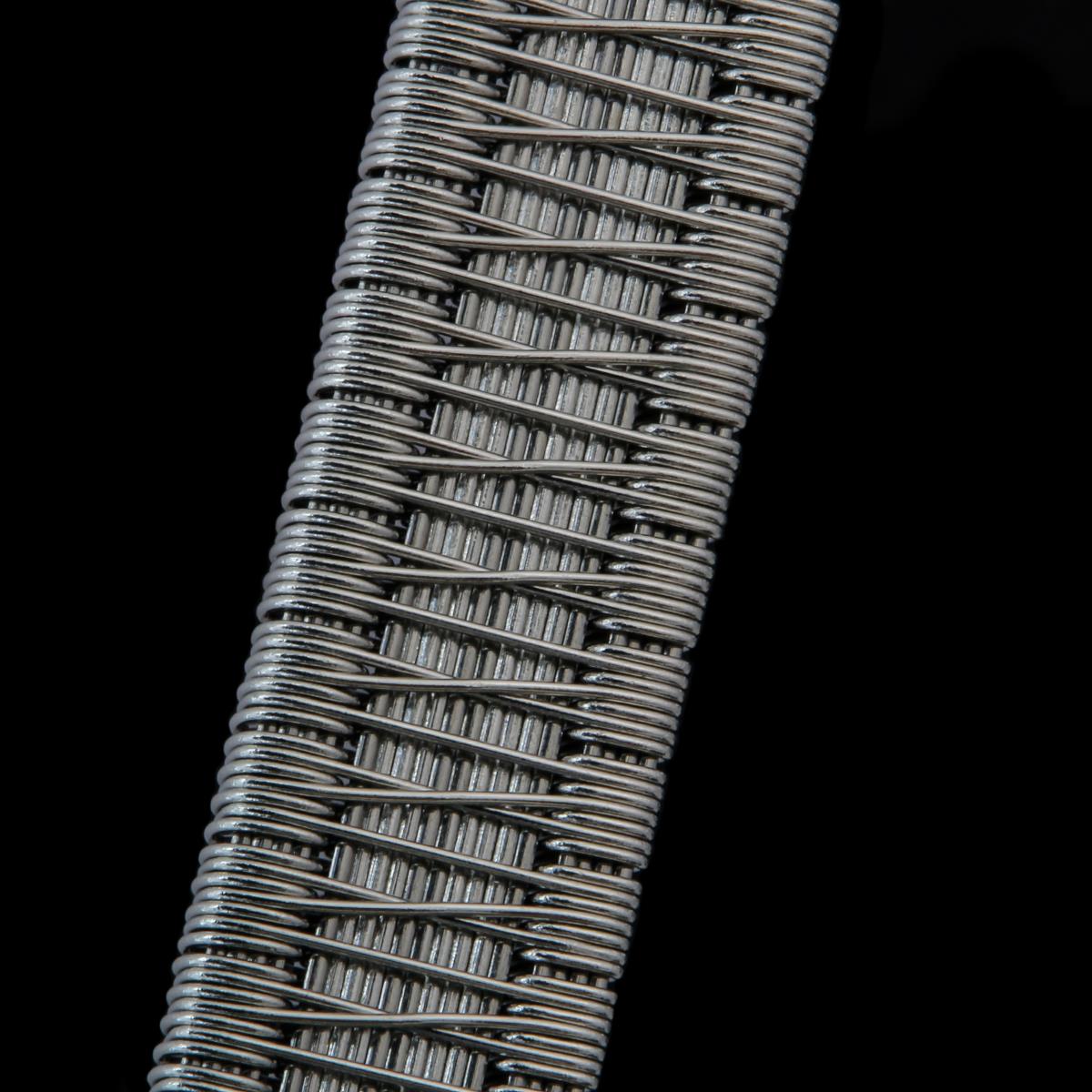

So I was talking to "The Shredder" last night, and showed him this pic. He liked it, so I figured I'd post it here. It's actually from a couple of years ago and may have already posted it back then. It's got nice aesthetics, and if I remember correctly it gave a pretty good vape, too. As much as I can appreciate the aesthetics of most of the builds are that are posted here, I really prefer a coil that has both form AND function.

The specs (I think) are 3 strands of 26g KA1, N80, and SS316L twisted together, flattened, then polished. I can't remember what the resistance ended up at.

Here's a couple other angle shots:

The specs (I think) are 3 strands of 26g KA1, N80, and SS316L twisted together, flattened, then polished. I can't remember what the resistance ended up at.

Here's a couple other angle shots:

Last edited:

First of all, no offense taken. I appreciate any insight you are willing to give so thank you.idk how long you've been building so please don't be insulted ... this is all purely to try and be helpful ...

The most difficult thing about zippers is getting 2 strand of twisted wire the have an even twist. Unless you twist from both sides, which is obviously difficult, the wires do not twist evenly from end to end. They will always start twisting from the chuck end (or the end that is doing the spinning). So that end will always be a bit tighter of a twist. The remedy for this is to twist until you have the pitch, on the chuck end, just a little wider than you want to end up with. Then flip the stick and twist the other end until it has the same pitch. This is obviously a ridiculous notion considering that a tenth of a mm difference is noticeable when it sets everything off just enough so that the humps don't line up across the coil. The quick fix for this is to twist one side until it breaks and then flip and twist the other till it breaks. But this leads to other problems. If the tension between the 2 wires isn't damn near perfect then your stick will break somewhere in the middle where the slack is, instead of at the chuck end. It also means your stuck with a super tight twist whether you like it or not. Not only does this limit the look of your build to a single outcome, it also affect how the coil functions. Super tight twists tend to be fraught with hot spots. Then comes the wrapping ... Twisted wire is springy as hell. It's already a PITA to get a twisted wire coiled nice and neat. Then you add another one and your trying to keep them lined up to get that zipper affect. Lots of pulling and adjusting and tightening ...

I know that looks like a lot of build up to a hard build. But, in the end it is not difficult. Once, you have a feel for how wire will act in most situations you'll develop intuitions that make all this stuff trivial even if you've never attempted the build before.

Good luck and let us know how it turns out

I'm pretty stoked to try this build and see how she vapes too. I'm thinking I'll use 28g ka1 and maybe just try it as a 4mm single coil. It's going into a DPro and onto a single battery unregulated squonk. I'm hoping it won't need too need too much wattage to function on there. If nothing else I figure I'll build up a pair of 2x28/38 ka1 fused claptons if it doesn't do well with this kind of situation. Well I'll try this after I get home tonight after work. Happy building all.

Sent from my LGMP450 using Tapatalk

The DPro24 (I'm assuming you have the 24 since I'm not sure you can fit a 4mm into the 22) is good for big, single, flavor coils. The drawback I find with the larger ID's in it is that the air hits mostly on the bottom ~1/3 of the coil. And between the cotton and needing to slam the coil as far down as you can ... there's not a lot of deck for the air to "bounce off of" to really give it good direct airflow. The plus side to this set-up is the chamber is reduced significantly with a wad of cotton and a big fat coil ... so that improves the flavor a bit.First of all, no offense taken. I appreciate any insight you are willing to give so thank you.

I'm pretty stoked to try this build and see how she vapes too. I'm thinking I'll use 28g ka1 and maybe just try it as a 4mm single coil. It's going into a DPro and onto a single battery unregulated squonk. I'm hoping it won't need too need too much wattage to function on there. If nothing else I figure I'll build up a pair of 2x28/38 ka1 fused claptons if it doesn't do well with this kind of situation. Well I'll try this after I get home tonight after work. Happy building all.

Sent from my LGMP450 using Tapatalk

So I was talking to "The Shredder" last night, and showed him this pic. He liked it, so I figured I'd post it here. It's actually from a couple of years ago and may have already posted it back then. It's got nice aesthetics, and if I remember correctly it gave a pretty good vape, too. As much as I can appreciate the aesthetics of most of the builds are that are posted here, I really prefer a coil that has both form AND function.

The specs (I think) are 3 strands of 26g KA1, N80, and SS316L twisted together, flattened, then polished. I can't remember what the resistance ended up at.

Here's a couple other angle shots:

Thats just plain purty thats what that is.

Here's an experimental trick that actually did what I wanted. Usually when I use a spool tamer for claptoning I have the winding feeding from the spool from the trailing side of the spool. That keeps the winding tight. Turn it around the other way so that it feeds from the leading side of the spool and it staggers perfectly like above.

Holy shit Chef! This puts that snake oil salesman in Norway to utter shame. Thats awesome!So I was talking to "The Shredder" last night, and showed him this pic. He liked it, so I figured I'd post it here. It's actually from a couple of years ago and may have already posted it back then. It's got nice aesthetics, and if I remember correctly it gave a pretty good vape, too. As much as I can appreciate the aesthetics of most of the builds are that are posted here, I really prefer a coil that has both form AND function.

The specs (I think) are 3 strands of 26g KA1, N80, and SS316L twisted together, flattened, then polished. I can't remember what the resistance ended up at.

Here's a couple other angle shots:

That’s such a damn beautiful coil. I need to get an ultrasonic cleaner... if that’s what it’s called so I can learn how to polish builds. It’s maybe one of the only things I have not at least attempted. Beautiful build!So I was talking to "The Shredder" last night, and showed him this pic. He liked it, so I figured I'd post it here. It's actually from a couple of years ago and may have already posted it back then. It's got nice aesthetics, and if I remember correctly it gave a pretty good vape, too. As much as I can appreciate the aesthetics of most of the builds are that are posted here, I really prefer a coil that has both form AND function.

The specs (I think) are 3 strands of 26g KA1, N80, and SS316L twisted together, flattened, then polished. I can't remember what the resistance ended up at.

Here's a couple other angle shots:

Yes!!!!This is like a Gatortail core with like a skip fuse binding on the twisted side. I did it to see if it would coil out of curiosity and it actually vapes nice. I made it kinda ugly but I’m not going through it again haha.

View attachment 131743

This gives me inspiration. Probably spin something up tomorrow. Thanks Shred

That looks really nice. I have a number of new atties to play with. I wish I had some other gauges of wire now, the DPro has some good sized post holes. On the bright side, the IRS is finally proceeding my return so hopefully not too long before I can order wire finallyMy last build was messy so I felt like doing something clean. This is just a basic skip fused staggerton.

View attachment 131764

View attachment 131769

Sent from my LGMP450 using Tapatalk

Thanks man it was just a build I did out of boredom. I rarely attempt to do builds that are meant to give an impression of any magnitude and if I ever do it’s usually because I’m SUPER bored or trying something new and I’m getting too wrapped up in it. I don’t use photoshop, I don’t use a professional camera or macro lense. Not that there is anything wrong with that. Just for me there is a kind of balance in everything I think. All you really need to get better at this point is 28g and 36 or 38 gauge. You get that fused clapton perfect and then you start working on the alien coil. Before you know it you’ll be starting with the ribbon wire and all the staple variations. I’ll always force myself to post something just to in turn retain my skill set. I made a couple of these for @St.Roostifer. Very interesting to feel the difference between Kanthal And N80. Takes a second to get used to.That looks really nice. I have a number of new atties to play with. I wish I had some other gauges of wire now, the DPro has some good sized post holes. On the bright side, the IRS is finally proceeding my return so hopefully not too long before I can order wire finally

Sent from my LGMP450 using Tapatalk

Fraliens 28g .3 ribbon 4 ply 36g